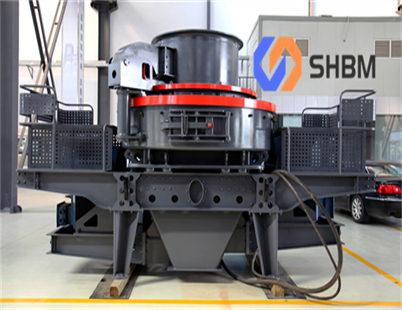

في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

Large and robust with a rigid four arm mainframe and integral countershaft; m 59 in head diameter Our Raptor cone crusher spare parts are designed to offer excellent performance with increased durability smoother operation and reduced maintenance expenses Now your closed circuit plant can be as mobile as your needs Versatility

الاستفسار عبر الإنترنت →

1 ·The disc feeder is a common equipment used to evenly feeding medium and fine grained materials It mainly allows the materials in the silo to be discharged and fed into the next equipment continuously and evenly saving labor It is usually suspended on a steel structure or installed at the discharge port of a hopper or silo for continuous feeding

الاستفسار عبر الإنترنت →

1 ·The dewatering screen is also called dewatering vibrating screen a common mining dewatering called sand and gravel dewatering screen mining dewatering screen coal slime dewatering screen tailings dewatering screen etc The main function of the machine is dehydration desliming and demediation to solve the problem

الاستفسار عبر الإنترنت →

The Double Roller Crusher is ideal for soft and medium hard rock applications Products & Services; Company; such as limestone clay iron ore coal and others They can also be used for secondary crushing of soft to medium hard rocks Thanks to their capability to achieve high reduction ratios low energy consumption and low wear in

الاستفسار عبر الإنترنت →

·Sometimes screening is also required before crushing For example the range of particle size of raw materials is large Large pieces of materials need to be coarsely crushed by jaw crusher while small pieces of materials can be directly screened before entering the subsequent equipment to avoid over crushing

الاستفسار عبر الإنترنت →

The roll crusher is the workhorse of coal size reduction to shear and/or compress the material From Encyclopedia of Energy The coefficient of friction between steel and most ore particles is in the range They are designed both to reduce the size of large coal lumps to less than 6 14 inches and also to feed materials out

الاستفسار عبر الإنترنت →

·Like the jaw crusher the cone crusher provides a relatively low cost crushing solution but there are application drawbacks that may make another crushing solution more appealing First cone crushers cannot accept all material sizes Any material fed to the crusher must be pre sized for that particular crusher usually 200mm or less

الاستفسار عبر الإنترنت →

·thyssenkrupp Industrial Solutions will supply two of its KB 63 130 gyratory crushers — which are set to be the largest in Australia — to Fortescue Metals Group s Iron Bridge magnetite

الاستفسار عبر الإنترنت →

2 ·At the same time however lithium ion batteries are considered a crucial technology in the world s transition to renewable energy storing electricity generated by the wind and the Sun Finding a source of lithium that doesn t cause more environmental destruction than necessary is key but a clean solution is complicated

الاستفسار عبر الإنترنت →

·trucks delivering ore or other reasons Crusher plug 160 2% of production time Chute plug 200 % of production time and large feeder openings must be provided for bins silos and tunnels If it is practical to obtain representative ore samples it is prudent to have testwork conducted to establish ore flow properties which will influence

الاستفسار عبر الإنترنت →

The roll crusher is the workhorse of coal size reduction to shear and/or compress the material From Encyclopedia of Energy The coefficient of friction between steel and most ore particles is in the range They are designed both to reduce the size of large coal lumps to less than 6 14 inches and also to feed materials out

·The crusher system is a critical part of the system Ritter 2016 It is the location and characteristics of the crusher station that is utilised in categorizing the IPCC systems into four types namely fixed IPCC semi fixed IPCC semi mobile IPCC and the fully mobile IPCC Dzakpata et al 2016; Ritter 2016; Abbaspour and Drebenstedt 2019a b

الاستفسار عبر الإنترنت →

Material coal limestone gypsum alum etc The hammer crusher we produced has a large crushing ratio generally 10 25 or high up to 50 high production capacity low energy consumption simple structure light quality easy operation and maintenance etc A mobile inspection and routine maintenance are necessary The operator should

الاستفسار عبر الإنترنت →

·Trommel Screen Machine Types JXSC supplies two types of trommel screen machines the mobile/portable and fixed trommel screen Our Rotary Screen We offer a wide range of sizes and capacities including custom made stationary gold wash plant or portable trommel screens to the needs of individual customers

الاستفسار عبر الإنترنت →

·The company finished off 2019 by winning a contract to supply a new primary jaw gyratory crusher for the Roy Hill iron ore mine in the Pilbara Western Australia

الاستفسار عبر الإنترنت →

The toothed roll crusher is specifically designed to crush fragile materials with medium hardness or less mainly used for crushing raw coal in large coal mines or coal processing plants It is widely utilized in various industries such as coal metallurgy mining chemical industry and building materials

الاستفسار عبر الإنترنت →

·This entry was posted in Coal Crusher and tagged coal mill New Energy Lithium Ore Mining Process Spodumene According to the hard rock crushing process the crushed product is generally 5 40mm combined with different design requirements of customers two end or three stage crushing high grade crushed products above 4 5%

Lithium crusher How to process lithium ore to get lithium carbonate Lithium ore crushing equipment Nickel ore crusher is used in nickel ore beneficiation process Cobalt ore beneficiation process equipment recommendation

الاستفسار عبر الإنترنت →

The output product of a jaw crusher was studied by Olaleye [7] and Mu [8] in terms of how it varies with ore 40 body strength as well as using Discrete Element Modelling DEM techniques

الاستفسار عبر الإنترنت →

The single toggle jaw crusher has less shafts and bearings compared to double toggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Double toggle jaw crushers In a double toggle jaw crusher the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.