في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

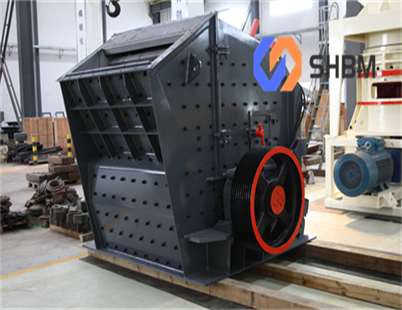

A crusher is a machine that reduces large rocks into smaller rocks gravel or rock dust Crushers are mainly used in the mining and construction industries where they are used to break down very large rocks and boulders into smaller pieces like a jaw crusher but shaped like a cone The ore is discharged through the smaller bottom output

الاستفسار عبر الإنترنت →

·Three crusher types are used to demonstrate these capabilities 1 Twin roll crusher 2 Cone crusher 3 Vertical Shaft Impactor VSI These show the nature and level of fidelity that is now possible to include in particle scale crusher models including breakage of non spherical particles and prediction of the product size distribution and

الاستفسار عبر الإنترنت →

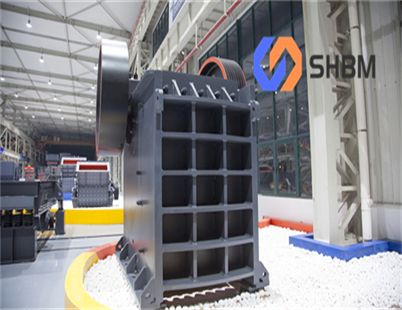

·The double jaw crusher is designed for crushing hard materials also quarried materials sand and gravel and recycling [4 5] crusher [4] The tie rod and compression spring ensure that the

الاستفسار عبر الإنترنت →

·Different jaw crusher designs will operate slightly differently but how they work is similar across the board All jaw crushers reduce large sized rocks ore or other materials by a compression

الاستفسار عبر الإنترنت →

·Chrome Ceramic are chrome bars with ceramic applied through the bar As with any chrome bar they do no perform well in applications with tramp metal or large feed sizes but they are effective in highly abrasive applications For this reason chrome ceramic blow bars are often used in secondary and tertiary crushing including asphalt crushing

الاستفسار عبر الإنترنت →

·MX Series Gyratory Crusher is mainly used in a very large primary crushing MX Series Gyratory Crusher has a unique crushing cavity design to ensure the best production capacity ore slag and other materials The maximum feed size is 450 mm 1000 mm Read More Track Mounted Jaw Crusher 20% Increased Production Capacity

الاستفسار عبر الإنترنت →

·The biggest concern here however is making sure all tramp metal is kept away from the high chrome blow bars Too much steel or steel that s too large can cause the bar to fracture If properly maintained and used only for crushing rocks high chrome bars will last the longest without having to be replaced Medium Chrome Blow Bars

الاستفسار عبر الإنترنت →

·Through pre screening the qualified part of the particle size can be screened out in advance reducing the amount of ore entering the crusher and relatively increasing the production capacity of the crusher In addition it can also be used to process ores with a large mud content to prevent the crusher from clogging

الاستفسار عبر الإنترنت →

4 ·Companies in South Africa supply chrome ore from the lower and middle group chromitites of the Bushweld complex and from the upper group chromitite seam UG2 in addition to platinum group minerals Chromite is a part of the spinel group which means that it is able to form a complete solid solution a mixture of two crystalline solids that

الاستفسار عبر الإنترنت →

Rent a crusher for processing concrete asphalt sand & gravel and millings Wide range of mobile jaw and impact crushers available From 90 to 385 TPH We have a large selection of mobile jaw and impact crushers available for rent Small Compact Crushers & High Capacity Aggregate Systems and everything in between

الاستفسار عبر الإنترنت →

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications These crushers use compression force to break large rocks and other materials into smaller rocks gravel and Since its inception the live shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

الاستفسار عبر الإنترنت →

A crusher is a machine designed to reduce the size of large rocks to smaller rocks gravel sand or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages that lead to separation of the mineral s from the waste gangue material Waste material can be discarded or recycled

الاستفسار عبر الإنترنت →

Single Roll Crushers Single Roll Crushers are typically used as primary crushers that provide a crushing ratio of up to 6 1 They crush materials such as ROM coal mine refuse shale slate gypsum bauxite salt soft shale etc while producing minimal with intermeshing roll teeth and a curved crushing plate they are extremely effective in

·Jaw Crushers are not a shaping crusher Because they typically produce an elongated flat and slabby product Jaw Crushers are usually followed by a secondary crusher such as a cone impactor or roll crusher for refining and further size These crushers come in a range of styles and sizes and are capable of handling low

الاستفسار عبر الإنترنت →

·A mining crusher reduces large rocks into smaller rocks gravel or rock dust Crushers can be used to reduce the size or change the shape of materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials as in rock ore so pieces of different compositions can be differentiated

الاستفسار عبر الإنترنت →

·There are two methods 1 Fragility coefficient method The crushability factor is the ratio of the crusher s ability to crush pending ore and the crusher s crushing medium hard ore under the same conditions Limestone is usually used as the standard medium hard ore and its crushability factor is one 2 Work index method

الاستفسار عبر الإنترنت →

This rock jaw crusher makes crushing hard rock and ore look easy Unmatched robustness and longevity Incorporating the latest technology the Jaw Crusher EB series consisting of a standard model range and Pro series delivers high performance thanks to the optimised geometry of the crushing chamber

الاستفسار عبر الإنترنت →

·Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers Crusher Selection For a hard rock mine application below 600 tonnes/hour select a jaw as the primary crusher Over 1 000 tph select a gyratory crusher Between these capacities you have a choice Source Chris Ottergren For a hard rock mine application

الاستفسار عبر الإنترنت →

Baker Mining and Metals jaw crushers are industrial grade continuous duty machines They take large pieces of rock ore concrete or other materials and crush them down Complete and ready to run including jaw crusher belts motor full enclosure guards all integrated on a steel skid; We bought a turn key ore processing system

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.