في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·Therefore this article shows analytical procedure of getting connection between operation mode parameters of the crusher and its capacity Zimin A I Muizemnek A Y and Zimin I A 2000 Capacity calculation of large jaw and cone crushers of the Higher Institutions Mining Journal 4 Google Scholar Taggart A F 1998 Handbook

الاستفسار عبر الإنترنت →

·The chamber structure parameters of the cone crusher are the key parameters that affect the performance of the crusher The bottom angle of the mantle α the length of the parallel zone l the eccentric angle γ and the rotating speed n are determined as the design variables of the dual objective programming model as shown

الاستفسار عبر الإنترنت →

·A small jaw crusher having a 250x400mm feed opening and a capacity of 5 20 tons per hour will cost less than a large jaw crusher with a 1 200×1 500mm feed opening and a capacity of 400 800 tons per hour The cost of a jaw crusher will be in direct proportion to the size of the feed opening and the capacity

الاستفسار عبر الإنترنت →

·A low grade graphite ore from eastern India was beneficiated by flotation to improve its quality The ore was composed of % ash and % fixed carbon

الاستفسار عبر الإنترنت →

·The key performance parameters of a cone crusher include the output; particle size and particle shape In previous research on cone crusher performance the output was calculated by integrating the mass flow field over a horizontal cross section of the crushing chamber Evertsson 2000 To accurately simulate the crushing process of

الاستفسار عبر الإنترنت →

·The cone crusher consists mainly of a mantle and a concave with the minimum distance between them defined as the closed side setting CSS The complex motion behaviors of particles in a cone crusher are influenced by operation parameters CSS eccentric angle and eccentric speed

الاستفسار عبر الإنترنت →

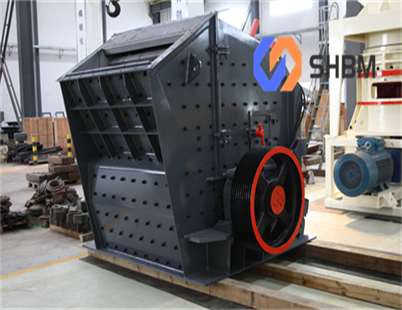

4 ·The hammer head of JXSC hammer crusher is cast from high manganese steel which has high density wear resistance and impact resistance The production capacity is high and the products are uniform; the required discharging granularity can be adjusted according to customer requirements

الاستفسار عبر الإنترنت →

used for modeling A Y51 cone crusher is investigated to establish the corresponding optimization model and tech nological parameters 2 Working principle and kinematic analysis of the cone crusher Working principle of the cone crusher When a cone crusher operates its moving cone surface repeatedly moves towards and away from its fixed

الاستفسار عبر الإنترنت →

·The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusher This is illustrated in Figure Reduction ratios in the following ranges are common for cone crushers 6 1 8 1 for secondaries 4 1 6 1 for tertiary and quaternary crushing

الاستفسار عبر الإنترنت →

·Like the jaw crusher the cone crusher provides a relatively low cost crushing solution but there are application drawbacks that may make another crushing solution more appealing First cone crushers cannot accept all material sizes Any material fed to the crusher must be pre sized for that particular crusher usually 200mm or less

الاستفسار عبر الإنترنت →

·The crushing of minerals and ore is of great industrial importance With global population growth urbanization and continuing improvements in living conditions the productivity and efficiency of existing crushers must be increased to meet the growing demand [] Cone crushers are characterized by a continuous operating cycle and may

الاستفسار عبر الإنترنت →

·The CSS is the most important machine control parameter for the cone crusher It can vary due to wear or intentionally as a result of operator or machine control decisions Here we explore the effect of small changes in the CSS on the flow and crusher performance CSS values of 11 mm base case 12 mm and mm are considered

الاستفسار عبر الإنترنت →

Roll crusher has a crushing ratio of 5 to 8 and are used for fine crushing It has a wide range of feed particle sizes up to 130mm and the discharge size is 0 45mm power Roll crushing surfaces operate at a fixed distance apart unlike the continually changing distances in a jaw or cone crusher The result of using this equipment is a

الاستفسار عبر الإنترنت →

·for the cone crusher and for prototyping parameters of a PID controller were determined in the Simulink/MATLAB® environment The simulation involved the optimisation of the control model as a function of the cavity level of and the power drawn by the cone crusher A self tuning control algorithm at PLC and SCADA level of control was

الاستفسار عبر الإنترنت →

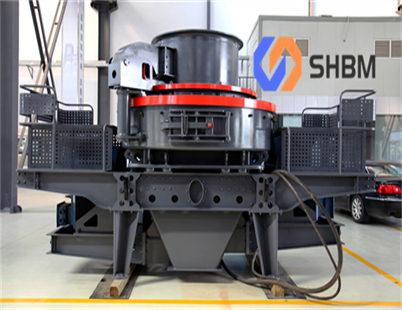

3 ·Rock crushing equipment and crushers are essential for construction mining and mineral processing Its main function is to produce sand for road construction or concrete aggregate It can crush various materials including granite limestone basalt river pebbles gold ore copper ore and other stone or ore crushing plants In addition to

الاستفسار عبر الإنترنت →

·The machinery used for model validation consists of two robust devices The first is an industrial type of machinery of 1 m diameter with m wide rolls Fig 2 The other is a lab scale type of the same machinery and has a diameter of m and m wide models have studded liners for the roller surface and use four

الاستفسار عبر الإنترنت →

2 ·Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles widely used in the quarrying metallurgical and allied industries Jaw crusher is one of the most commonly used primary crushers in the ore processing plant with a capacity range of 1 1000tph There are two types of feeding

الاستفسار عبر الإنترنت →

3 ·Graphite ore beneficiation includes gravity separation flotation and magnetic and electric separation; it is widely used in separating natural graphite flake graphite crystalline graphite graphite in granite According to the specific composition and properties of the ore JXSC will combine multiple methods for comprehensive processing to achieve the

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.