في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

Throughout this paper we will explore the principles of ore sorting and how crushing and screening can impact ore sorting performance Why Use Ore Sorting Ore sorting is one of the oldest methods of mineral processing there are documents from antiquity that show people hand picking rocks containing valuable metals and minerals while

الاستفسار عبر الإنترنت →

·In order to improve the output and equipment utilization the gold processing plants generally follow the principle of more crushing and less grinding to reduce the particle size of the ore to be ground Commonly used equipment is as table 1 Table1 Common Used Gold Crushing and Screening Machines Gold crushing and screening

الاستفسار عبر الإنترنت →

·Sample processing is divided into coarse crushing and fine crushing Every stage also includes crushing screening uniformly mixing and splitting The processing method is suitable for lateritic nickel ore and complies with the requirements of mine 20% is thickened and pumped to the lone distance ore slurry pipeline transportation system

الاستفسار عبر الإنترنت →

·This is necessary to handle the coarser ore and thoroughly disintegrate any clay balls which would otherwise cause serious trouble in the subsequent secondary crushing steps It may also be necessary to incorporate vibrating screens into the circuit to improve screening efficiency in removing the fines along with spray and wash water

الاستفسار عبر الإنترنت →

·the continuous stable and safe operation of ore crushing and screening In the practice of produc tion the crushing and screening process is related to the particle size of raw ore the particle size of long production line in the ore crushing system and the correct design of crushing interlock con trol is the fundamental guarantee of

الاستفسار عبر الإنترنت →

Continuous Barge Unloaders Heyl & Patterson from HMA Materials Handling offers high capacity machines that have solved a variety of unloading problems for many customers Diverse barge cargoes such as coal iron ore bauxite alumina corn wheat soybean sand agricultural by products wood chips and limestone can be quickly and successfully

الاستفسار عبر الإنترنت →

·At Terex MPS we produce a range of crushing and screening equipment to suit all of your crushing and classifying needs Whether you re on the move need a temporary solution or have a large static operation we will have the equipment for your needs Terex Minerals Processing Systems Terex Malaysia Celebrates Innovation and

الاستفسار عبر الإنترنت →

3 Screening machines for iron ore and coal The crushing and screening systems for iron ore processing vary widely depending on whether a magnetite or hematite deposit is being mined While good quality magnetite is now dry processed hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminations

الاستفسار عبر الإنترنت →

·different/multiple crushed products within a designed crushing circuit Purpose and Goals The purpose of this master thesis will be further development of the Cost Analysis for Crushing and Screening Model The base of this project will be Cost Analysis for Crushing and screening Part I

الاستفسار عبر الإنترنت →

·development of mobile crushing plant and systems According to different crushing requirements mobile crushing plant can follow screening after crushing process or crushing after screening process The crushing plant with high flexibility can be combined into either a two section screening system of coarse and fine crushing or a three

الاستفسار عبر الإنترنت →

Pilot Crushtec s crushing and screening solutions are key for a wide range of applications within the energy minerals sector and the company has built a significant footprint in these industry segments The flexibility of our mobile and modular equipment allows customers to tailor solutions to match diverse ore characteristics and

الاستفسار عبر الإنترنت →

·01 Nickel ore crushing and screening stage The nickel crushing and screening stage often adopts a three stage one closed circuit crushing and screening process The raw ore is fed into the first stage crushing from the feeding bin and then enters the second stage crushing after crushing and is crushed to a certain particle size and

الاستفسار عبر الإنترنت →

The wide range of options available with our mobile screens give you the ability to configure your system to suit a variety of screening applications including aggregates recycling and sand and gravel As with every Sandvik product experience insight and technology set our screening solutions apart from the crowd

الاستفسار عبر الإنترنت →

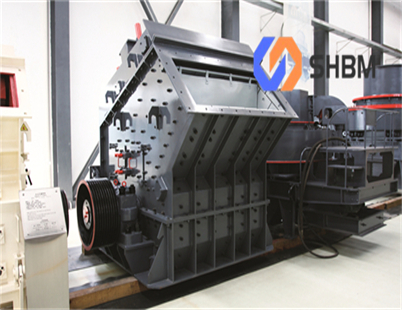

·The impact crusher can be used in the medium crushing and fine crushing stages because the crushing method is impact crushing and the ore can be selectively crushed along the cleavage plane and bedding plane Especially for the mica embedded in the ore and the thick sheet mica the impact crusher can effectively separate it from the

الاستفسار عبر الإنترنت →

·The ore is crushed and any low grade ore observed visibly by the operator is sent to the reject stockpile after screening at 75 mm The ore is dried and oversize 30 mm fraction sent to reject Successive crushing and screening operations give a plant feed at −6 mm The feed is upgraded from % to % Ni by selective mining blending

الاستفسار عبر الإنترنت →

·Crushing & Screening Technology The Terex ® MTJ1175 Modular Jaw Crusher features the rugged MTJ1175 jaw for high production Its hydraulically actuated wedge system allows closed side settings to be made quickly and easily It features the Terex ® JW42 single toggle jaw crusher It has a fully painted steel structure

الاستفسار عبر الإنترنت →

·Hydrometallurgy is a process used for nickel ore that has a grade of < % while pyrometallurgy is still used for nickel ore that has a Ni content of < 3% At present the most common

الاستفسار عبر الإنترنت →

·Crushing and screening The mined copper nickel sulfide ore is sent to the crusher for coarse crushing The ore particles that fail to pass the coarse crushing process directly enter the secondary

8 2010 RTIO Argyle Diamond Mine crushing & screening 200 000 t contaminated ore 9 2009 BC Iron Nullagine trial crushing of 120 000 t of Hematite Iron Ore 10 2008 BHP Billiton Ravensthorpe Nickel Operations crushing of 200 000 t Nickel ore 11 2007 Fox Resources Radio Hill Mine Crushing of Nickel Ore at Karratha

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.