في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

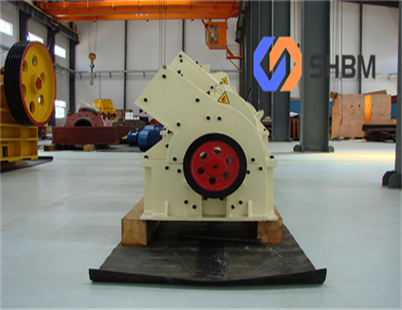

·The basic working principle of an impact crusher The fundamental working principle of an impact crusher is fairly straightforward yet its impact force can be substantial The machine crushes materials by applying a high speed impact force causing them to break into smaller pieces

الاستفسار عبر الإنترنت →

·Let s see its working principle and structure in details Email hm404298359 Toggle navigation Home Impact Crusher VS Jaw Crusher:What Are the Differences Message Beneficiation of Gold silver Polymetallic Ore 2022 04 12 09 04 47 4 Siderite Ore Extraction Method 2022 03 31

الاستفسار عبر الإنترنت →

·Gyratory cone crushers are powerful machines that have revolutionized the crushing industry Their unique design and superior performance make them a popular choice for a wide range of applications from mining and construction to recycling and chemical processing In this article we explore the many advantages of gyratory cone

الاستفسار عبر الإنترنت →

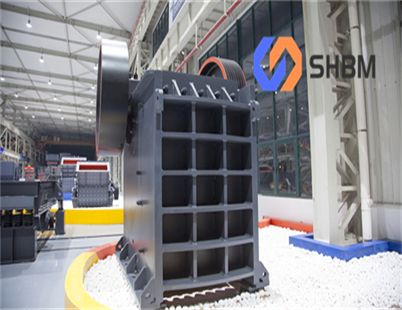

A jaw crusher is a device that is used in an industrial Jaw Crusher Working Principle Manufacturers Exporters and exporters in Delhi India Phone Number 91 9891445495 businesses require a jaw crusher Industries need different ore or materials for different sizes to manufacture the ultimate product To obtain the size and surface area

الاستفسار عبر الإنترنت →

The jaw crusher consists of two vertical jaws that are aligned to each other One of the jaws is fixed while the other jaw moves back and forth The working principles of gold ore crushers vary depending on the type of crusher However most gold ore crushers use a combination of compression impact and shear forces to break down large

الاستفسار عبر الإنترنت →

·To crush the of coal in a Primary Jaw Crusher Blake Jaw Crusher and determination of average product size by the use sieve shaker MATERIALS / APPARATUS REQUIRED 1 Coal 2 Different sieve screens of ASTM size 3 Black jaw crusher 4 Weight balance 5 Ro Tap sieve shaker THEORY Blake Jaw Crusher It has its moving jaw

الاستفسار عبر الإنترنت →

Jaw Crusher Working Principle A jaw crusher uses compressive force for breaking of particles This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates A jaw or toggle crusher consists of a set of vertical jaws one jaw is kept stationary and is called a fixed jaw while the other

الاستفسار عبر الإنترنت →

·Ore Jaw crusher is a device that uses the relative rotation of two jaw plates to crush materials to the required particle size under the action of extrusion shear and friction In iron ore crushing the working principle of jaw crusher is mainly reflected in the following steps 1 Motor drive The motor drives the eccentric shaft to rotate

الاستفسار عبر الإنترنت →

·In the history of crushers both chronologically and by virtue of its standing in the field of heavy duty crushing the Blake jaw crusher stands first in the list All of the large heavy duty primary crushers of the jaw type are built around the Blake principle which for simplicity and brute strength is unsurpassed by any mechanism thus far devised for

الاستفسار عبر الإنترنت →

·Jaw crusher is the commonly used crushing equipment in mining architectural material and other industries Correct operation is one of the important factors to ensure the continuous and normal operation of the jaw crusher Improper operation may reduce the jaw crusher efficiency and even endanger the life of the operator

الاستفسار عبر الإنترنت →

·Jaw Crusher Working Principle The material to be crushed is admitted between two jaws from the top The material caught between the upper part of the jaws is crushed to a smaller size during forward motion by compression The crushed material then drops/falls into the narrower space below during the backward motion and is recrushed

الاستفسار عبر الإنترنت →

5 ·5″ x 7″ High Reduction Ratio Jaw Crusher 2″ to 6 Laboratory Crusher US $ 6 000 Sale 4″ x 5″ Laboratory Jaw Crusher 911MPEJC100 Large Industrial Rock Crushers

Ore Crusher Iron ore grinder Calcite Crusher Graphite Crusher extec c12 crusher specification and stone crusher extec c12 crusher specification extec c12 crusher specification Home > Crusher Solution 07 > extec c12 crusher specification capacity processing a wide range of materials including hard rock

الاستفسار عبر الإنترنت →

·Stone Crusher also known as rock crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust It utilizes a high pressure force to crush the rocks and is widely used in various industries such as construction mining metallurgy and recycling

الاستفسار عبر الإنترنت →

·1 Introduction The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1] [2] [3]] In recent years with the growth of the world s population the development of urbanization and the improvement of living standards the demand for the ore continues

الاستفسار عبر الإنترنت →

·Ore Jaw crusher is a device that uses the relative rotation of two jaw plates to crush materials to the required particle size under the action of extrusion shear and friction In iron ore crushing the working principle of jaw crusher is mainly reflected in the following steps 1 Motor drive The motor drives the eccentric shaft to rotate

·Jaw Crusher A machine for crushing rock or ore between two heavy steel jaws Working principle of jaw crusher Jaw crusher is composed of main frame eccentric shaft flying wheel toggle plate jaw plate tension rod fixed jaw movable jaw and so on; among these parts the toggle plate can secure the whole body The motor transmits

الاستفسار عبر الإنترنت →

·In this study the comminution methods of graphite bearing ore were compared by using five different crushing methods namely a jaw crusher a roll crusher uniaxial compression tests and a new type of continuously compressing crushers These new continuously compressing crushers were available in laboratory and pilot scales

الاستفسار عبر الإنترنت →

Aimix s PE series ore crusher can crush large pieces of limestones The largest broken particle size is 1000 1200mm Parameters of Aimix s Jaw Ore Crusher Model Feed opening size mm size mm and so on These crushing machines have different working principles and are suitable for different working environments

الاستفسار عبر الإنترنت →

Many of these materials are hard tough or brittle so crushing them to smaller sizes is an ideal application for robust rugged and durable jaw crushers The Working Principles Of A Jaw Crusher All jaw crushers operate on the same straightforward principle; two hard faced heavy plates or jaws crush large particles between them

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.