في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·Be different from than jaw crusher impact crusher the cone crusher is a type of compression crusher innovative designed with a cone shaped inlet from where the object material is put in for crushing reduces material by squeezing or compressing it until it gets smaller discharges at the bottom Model Feeding Size mm Discharging Size

الاستفسار عبر الإنترنت →

This combination is mainly encountered in floor models that can accommodate large sample pieces such as the BB 300 jaw crusher The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size For Retsch jaw crushers this lies between 26 and 220 A high value reflects the capacity of

الاستفسار عبر الإنترنت →

·model of the jaw crusher geometry was designed using the software SketchUp Boulder CO USA based on the Otsuka Iron W orks manual as well as direct measurements of the discharge opening and

الاستفسار عبر الإنترنت →

1 ·Jaw crushers are used mainly in first stage primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the up thrust toggle RockSizer / StoneSizer model and down thrust toggle RockSledger model

الاستفسار عبر الإنترنت →

·The equipment used includes jaw crusher nickel ore ball mill nickel ore flotation machine rotary dryer spiral classifier etc Technical Requirements The flowchart is just for reference The process is adjustable according to the site requirements but part placement cannot be changed Foundation dimensions of equipments are subject to our

5 ·Cone crushers have a central role in the processing of quarry rocks besides coarser ore preparation in several mineral processing plants This is particularly true in the case of Itabirite iron ore preparation plants in Brazil so optimizing their performance is of central importance for reaching maximum productivity of the circuit The work presents

الاستفسار عبر الإنترنت →

·The equipment used includes jaw crusher nickel ore ball mill nickel ore flotation machine rotary dryer spiral classifier etc Technical Requirements The flowchart is just for reference The process is adjustable according to the site requirements but part placement cannot be changed Foundation dimensions of equipments are subject to our

Contribute to hedaokuan/fr development by creating an account on

الاستفسار عبر الإنترنت →

Jaw Crushers A jaw crusher is a compression type crusher comprised of a fixed jaw and moving jaw positioned in a V The movable jaw compresses material against the fixed jaw crushing the material to the desired size View Model Superior 4763B Liberty Bolted Feed Opening 47" x 63" Capacity stph 605 1 210 HP Range 350 View Model

الاستفسار عبر الإنترنت →

·The gold ore crushing process often uses jaw crusher for coarse crushing standard cone crusher for medium crushing and short head cone crusher and roll crusher for fine crushing Most medium and small gold processing plants use two stage closed circuit crushing and large scale processing plants use three stage closed circuit crushing process

الاستفسار عبر الإنترنت →

There are multiple mathematical models for equipment for example the crusher mechanistic model Evertsson 2000 crusher empirical model Whiten 1972 screen model Karra 1979;Soldinger 2002

الاستفسار عبر الإنترنت →

·However the predictive models stated in this study should be implemented to several portable jaw crushers to observe the similarities or difficulties in quantifying SRR as a function of rock

·Essa® JC5000 Jaw Crusher Rugged and dependable the Essa® Model JC5000 Jaw Crusher is the largest model in the Essa range of highly regarded heavy duty jaw crushers M 06 23 11000 21 ENG V3 Product datasheet Benefits Improved quality Simple jaw gap adjustment provides good control of product sizing while minimising

الاستفسار عبر الإنترنت →

·In this paper a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle the crushing torque and crushing power

الاستفسار عبر الإنترنت →

2 ·A variety of models are available Get the free price list Capacity 20 800 t/h customized Max Feeding Size 130 mm 1000 mm; According to Model Motor Power 220 kw; According to Model Description Standard jaw crusher output particle size is large usually 100 350 mm and secondary crushing is required; It can directly process bulk

الاستفسار عبر الإنترنت →

·d It is required to feed the ore with a uniform particle size otherwise the crusher is easy to be blocked and the miner must be set before crushing e It is suitable for crushing massive ore and sometimes the discharge particle size is too large for strip or flake ore A jaw crusher works in Morocco s 500tpd silver ore dressing plant

الاستفسار عبر الإنترنت →

·The primary crusher is normally a jaw crusher which is fed with blasted rock material A layout of a size reduction plant for comminution of a nickel rich ore is shown in Figure 2

الاستفسار عبر الإنترنت →

·Jaw Crusher Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses When the two jaw plates come together the material is crushed; when the plates move apart material smaller than the discharge opening is released from the bottom The crushing action is

الاستفسار عبر الإنترنت →

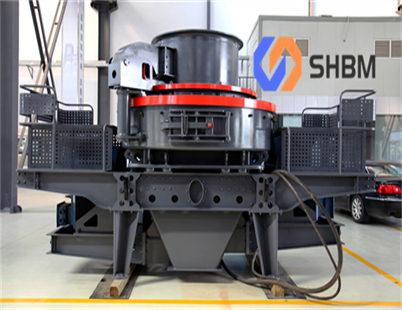

What Is A Jaw Crusher MENU Search G Model Vertical Shaft Impact Crusher L Model Screens Grizzly Screen Inclined Screen Horizontal Screen Dewatering Screen Scalping Screen Wet Processing of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed

الاستفسار عبر الإنترنت →

5 ·The Senya 5 Portable Jaw Crusher has a 40 kilowatt Yanmar powered electric generator installed just under the feeder This single generator can power the MICRO crusher conveyor and screen plant Boost efficiency further with the optional step down transformer upgrade option for on site 220 voltage and 110 voltage power Model 50

الاستفسار عبر الإنترنت →

·The side setting in crusher like jaw crusher is the distance between the fixed jaw and the moving jaw at the bottom of the crushing cavity A side can be set to ensure that the garment size is consistent with the sewn one The initial breaking up of ore is done by one of two types of jaw crushers which are known as single toggle and blake

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.