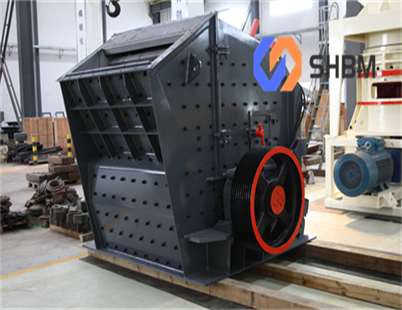

في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·Phosphate rock contains various gangue minerals including silicates and carbonates which need to be reduced in content in order to meet the requirements of the phosphate industry Froth flotation has become an integral part of phosphate concentration process In this study double reverse flotation was applied to recover apatite from

الاستفسار عبر الإنترنت →

·feed ore kg rice bran oil dose/ton feed of phosphate ore or kg oleic acid collector dose/ton feed of phosphate ore and cleaning reflotation of phosphate concentrates are the optimum condi tions for beneficiation of Sibaiya phosphate ores On cleaning reflotation the phosphate ore feeds of samples 1 medium P 2 O

الاستفسار عبر الإنترنت →

In this paper the process of direct reduction roasting using magnetic separation to produce direct reduction iron DRI from high phosphorus oolitic hematite using coal slime and blast furnace dust as reductant is investigated The possible use of slime coal and blast furnace dust as reductant and the dephosphorization behavior during the process of direct

الاستفسار عبر الإنترنت →

·process is carried out at pH 9 10 using sodium silicate as a Disposal of ore dressing plant tailings is a major Hamrawein phosphate ore with 22% P 2 O 5 is enriched to 29% P 2 O 5

الاستفسار عبر الإنترنت →

·The ore flotation process is one of the commonly used methods for phosphate ore beneficiation To ensure good flotation effects factors such as grinding fineness slurry concentration chemical system aeration and stirring flotation time and flotation process selection should be strictly controlled In addition to these factors the

الاستفسار عبر الإنترنت →

·The flotation capacities of the soybean oil sunflower and their mixtures were all evaluated at neutral pH of the pulp In this sense Fig 4 shows that the highest grade % recovery % and separation efficiency % were obtained for the mixed collector Then follow the results obtained by sunflower oil with the percentages of

الاستفسار عبر الإنترنت →

Abstract :Based on a large number of documents the author summarizes five kinds of processes for the treatment of phosphate ore dressing wastewater in present China s phosphorus ore dressing process is mainly based on

الاستفسار عبر الإنترنت →

NH 4 H 2 PO 4 mono ammonium phosphate MAP has become a leading phosphate fertilizer product worldwide Ammonium phosphates are produced by reactions of ammonia and phosphoric acid resulting in the formation of the mono basic salt A batch crystallizer in a pilot setup was utilized to produce pure MAP crystals using a fractional experimental

الاستفسار عبر الإنترنت →

·The dominant flotation process currently used for processing of siliceous phosphates in Central Florida is the Crago Double Float process Giesekke 1985; Zhang et al 1997 The simplified flotation flowsheet is given in Fig this process after desliming and sizing the ore is conditioned with fatty acids and fuel oil at a pH of

الاستفسار عبر الإنترنت →

·Beneficiation also known as mineral dressing or ore processing may involve a variety of operations such as size reduction size separation mineral separation dewatering and thermal processing Almost all phosphate ores require beneficiation to meet commercial specifications concerning particle size moisture content or chemical analyses

الاستفسار عبر الإنترنت →

·Coal based reduction followed by magnetic separation is an effective way to recover iron from high phosphorus containing oolitic hematite ore Given that high quantities of dephosphorization agent are needed to obtain low phosphorus reduced iron a novel approach is proposed by the authors Without prior phosphorus removal the phosphorus

الاستفسار عبر الإنترنت →

·Magnetizing roasting of oolitic hematite ore from western Hubei Province was investigated The mechanism for reduction roasting of oolitic hematite ore was discussed and analyzed It is found that flash magnetizing roasting magnetic separation process is a promising approach for the processing of oolitic hematite ore from western

3 ·conservation in the dressing plants and positive uses of solid wastes It is deposits and have high economic value to mine and process [9] Mining Engineering 2 Phosphate ore processing techniques are depending on the type of phosphate minerals and associated gangue The most abundant phosphate deposits are the marine sediments

الاستفسار عبر الإنترنت →

·Rare earth elements REEs are defined as lanthanides with Y and Sc Rare earth occurrences including the REE bearing phases and their distributions measured by rare earth oxides REOs in the streams of processing a phosphate ore were determined by using MLA the mineral liberation analysis and EPMA the electron probe

الاستفسار عبر الإنترنت →

·The conventional phosphate ore crushing process is a closed circuit of every three sections that is an operation of coarse crushing medium crushing and a section of screening operation Then is the ore beneficiation process of Phosphate Hill mine The aim of the ore beneficiation process is to achieve the enrichment of the phosphate which

الاستفسار عبر الإنترنت →

·As an important chemical mineral raw material phosphate ore is the main source of phosphate and elemental phosphorus With the continuous exploitation of phosphate resources high grade and easy to dress phosphate mineral resources are gradually decreasing and the development and utilization of medium and low grade

الاستفسار عبر الإنترنت →

【Process Introduction】 According to different ore properties of phosphorite(phosphate rock) Xinhai designs many processes for it such as flotation gravity separation chemical leaching combined dressing photoelectric sorting etc Flotation is widely used in phosphate including direct flotation reverse flotation reverse flotation and flotation and double

الاستفسار عبر الإنترنت →

·In the development and utilization of copper resources the grading operation of the copper ore beneficiation plant is also an important production link in the separation of copper ore As the difficulty of copper mining and sorting increases the requirements for screening efficiency and classification efficiency are getting higher and

الاستفسار عبر الإنترنت →

2 ·We provide crushing washing & screening machine grinding classifying magnetic separation flotation gravity separation tailings treatment laboratory and other beneficiation processing equipment to global customers It is widely used in various mining industries such as aggregate rock ore/mineral and sand production lines We are

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.