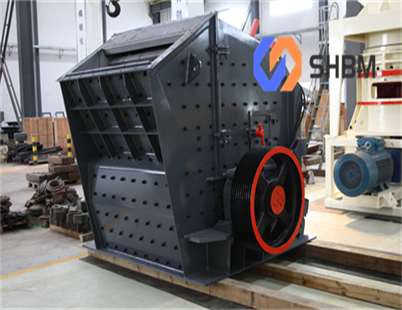

في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·The process of separating the components is done using gravity as the major criteria GRAVITY SEPARATION IN ORE DRESSING By to the gravity concentrations techniques towards tin oxide

الاستفسار عبر الإنترنت →

·Tin ore is a type of mineral ore that contains tin a soft malleable silvery white metal Tin is commonly used in various applications including as a coating for other metals to prevent corrosion in the production of solders as a component in electronics and in the manufacturing of tin cans Tin ore is typically found in rocks and minerals often in

الاستفسار عبر الإنترنت →

·calor other applications In the more common situations the basic steps in the process of recovery can be summarized as follows • Comminution or crushing and grinding to prepare the ore for the following separation steps • Physical separation or mineral dressing or beneficiation to separate the

الاستفسار عبر الإنترنت →

·The dressing of scheelite ore is a complex process involving multiple steps and technologies By rationally selecting and optimizing dressing methods and processes the recovery rate of tungsten and the quality of the concentrate can be effectively improved providing high quality raw materials for the smelting and application of tungsten

الاستفسار عبر الإنترنت →

·How to extract tin from tin ore Rock Tin Ore Extraction; In general the rock tin ore processing machine of gravity selection is generally used and the ore dressing of tin ore with a high degree of dissociation of the monomer is basically the same as the ore dressing of gold ore and the better ore dressing index can be obtained by simple

Request PDF On Dec 31 2021 T N Matveeva and others published Flotation extraction of tin from tailings of sulfide tin ore dressing using thermomorphic polymer Find read and cite all the

الاستفسار عبر الإنترنت →

·3 Jig Concentrator/Jig Separator is one of the ideal devices in energy saving gravity separation mainly used in the mining industry for ore dressing such as diamond tungsten tin manganese ilmenite hemtite rutile sand etc The maximum feeding particle size is 6 30mm and can be reach 30mm in producing sand ore jig

الاستفسار عبر الإنترنت →

·Therefore magnetic separation and flotation methods will be used in tin ore dressing Tin ore extraction process flow 1 Ore washing and desliming This step is aimed at raw materials with high mud content and strong cementation Such raw materials must be washed and desliming before crushing

الاستفسار عبر الإنترنت →

Mineral processing art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy

الاستفسار عبر الإنترنت →

The process of extracting tin from tin ore varies according to the source of the ore deposit and the amount of impurities found in the ore The tin deposits in Bolivia and England are located deep underground and require the use of tunnels to reach the ore 2 The ore enters the cleaning or dressing shed adjacent to the mining operation

الاستفسار عبر الإنترنت →

·Tin is a chemical element with the symbol Sn and atomic number 50 It is a post transition metal in group 14 of the periodic is a soft metal that is malleable ductile and corrosion resistant making it useful in alloys and Discovery Naming and Isolation Tin has been known since ancient times The earliest recorded use of tin

الاستفسار عبر الإنترنت →

· Abstract Mineral beneficiation is a process by which valuable constituents of an ore are concentrated through a physical separation process In the present investigation tin ore samples

الاستفسار عبر الإنترنت →

·This type of ore is generally processed by flotation which concentrates the gold in the non ferrous ore concentrate and then recovers the gold during the smelting process Gold can be obtained by cyanidation from gold bearing concentrates produced by the flotation of sulfide minerals in mines

الاستفسار عبر الإنترنت →

Tin processing Mining Concentrating Vein deposits such as those in Bolivia and the United Kingdom usually occur in granite formations and are recovered by conventional underground hard rock mining techniques In deep mines primary crushing equipment is usually located underground in order to reduce the ore to a manageable size before

الاستفسار عبر الإنترنت →

·Theorists interested in urbanisation believe that the process involves more than simple increase in size and that what is important is not a pyramid locating towns in terms of wealth and size but

·In the actual beneficiation process the selection of tin ore beneficiation process and equipment is often determined according to various factors such as the nature of tin ore dressing plant conditions and investment budget If you want to separate tin ore more economically and environmentally you should first carry out a beneficiation test

الاستفسار عبر الإنترنت →

21 · 86 13879771862 Tel or WhatsApp Chat Home; Equipment Gold Mining Equipment Rotary Scrubber; Mobile Gold Wash Plant

الاستفسار عبر الإنترنت →

2 ·The shaking tables gravimetric tables shaker tables gold shaking table are the most widely used and efficient gravity separation equipment for fine ore separation It is widely used in the beneficiation of rare metals and precious metal ores such as gold copper tin tantalum niobium iron manganese chromium etc

الاستفسار عبر الإنترنت →

·Magnetizing roasting of oolitic hematite ore from western Hubei Province was investigated The mechanism for reduction roasting of oolitic hematite ore was discussed and analyzed It is found that flash magnetizing roasting magnetic separation process is a promising approach for the processing of oolitic hematite ore from western

الاستفسار عبر الإنترنت →

·Tin ore has very low grade tin content % so it needs to experience mineral processing to generate the concentrate with tin content 40 70% Gravity separation is the main process for tin ore mineral processing There are other physical processes such as flotation and leaching The low grade tin ore generated during mineral

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.