في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·regolith processing reagent processing product storage & delivery power manufacturing etc Basalt Rock Basalt a mafic extrusive rock is the most widespread of all igneous rocks and comprises Equipment Shelters Maintenance Hangars Dust free zones Thermal Wadi sfor night time

الاستفسار عبر الإنترنت →

Advantages of Granite / Basalt Crushing Processing Line 1 The granite/basalt crushing processing line has the advantages of high automation large crushing ratio high production efficiency and large processing capacity The crushed products are cubic with low needle flake content no internal cracks and high compressive strength 2

الاستفسار عبر الإنترنت →

·Some features of the mechanism of basalt melt glass formation are reported The effect of the characteristics of the basalt melt on the quality of continuous fibers is demonstrated The advantages of multioperator technology for production of continuous basalt fiber are substantiated

الاستفسار عبر الإنترنت →

Refining basalt to a finely crystallised glass ceramic Multotec s cast basalt wear resistant material provides an extremely durable long lasting lining for static plants bearing large volumes of abrasive and/or corrosive Supplied as both a pipe and tile lining solution cast basalt is ideally suited for wet material handling applications with lower impacts such

·The process of crushing and screening basalt into materials for road construction typically involves the following steps Crushing Process Firstly raw basalt is collected from the collection site and transported to the processing site At the processing site primary crushing equipment like jaw crushers is used to break down large pieces of

الاستفسار عبر الإنترنت →

·Additionally understanding the formation process and typical locations where basalt rocks are found can also aid in identification Color and Texture Easily distinguishable by its dark color and fine grained texture identifying basalt rocks can be straightforward for geology enthusiasts Basalt rocks typically exhibit the following

الاستفسار عبر الإنترنت →

2 Hardware configuration cost The hardware configuration refers to the processing equipment of basalt which accounts for the majority of the total cost Different processing scales determine

الاستفسار عبر الإنترنت →

·The complete set of basalt sand production line with a daily output of 500 tons is used Large pieces of basalt are evenly fed into the jaw crusher by the feeder for preliminary crushing; then they are sent to the impact crusher/cone crusher by the

الاستفسار عبر الإنترنت →

6 ·We propose to Customers Plants Designed Projects Technologies and Process Equipment for producing of basalt fibers and materials made on their basis Process Equipment for manufacturing of basalt of continuous fiber BCF Process lines TE BCF 2000 2500 Installation and launching of the Process Equipment for BCF production

الاستفسار عبر الإنترنت →

Abrasive Resistant Basalt Tiles are used to protect equipment and structures from abrasion and wear caused by the flow of abrasive materials Scan WhatsApp 0086 21 33780199 service time 9 00 21 00 Cast basalt Process Natural gas is used for melting basalt stone in melting furnace Natural gas is currently very clean and environmentally

·The process of crushing and screening basalt into materials for road construction typically involves the following steps Crushing Process Firstly raw basalt is collected from the collection site and transported to the processing site At the processing site primary crushing equipment like jaw crushers is used to break down large pieces of

الاستفسار عبر الإنترنت →

·Subsequently the as prepared basalt melt was put into a home made single hole fibre drawing crucible By adjusting the fibre drawing temperature liquid level and the rotating speed a basalt monofilament was continuously drawn out without any interruption or breakage The fibre drawing process lasted for 4 h without fracture

الاستفسار عبر الإنترنت →

·Basalt fiber BF is a new kind of eco friendly natural fiber which is made of high quality basalt rocks at a melting temperature range of 1450 °C ∼ 1500 °C This process is repeated multiple times to create coarse aggregate templates as depicted in Fig 6 Download Download high res image 413KB Download Download full size image

الاستفسار عبر الإنترنت →

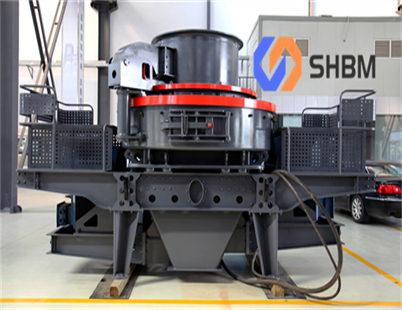

Basalt Grinding Mill The basalt processing plant usually includes two major steps crushing process and grinding process respectively So as for basalt processing equipment the following basalt grinding mills are recommended Project Case Quartz Production Line in Indonesia 10 T/H Coal Production line in Vietnam Limestone production line

الاستفسار عبر الإنترنت →

·CBF TE BCF 1000 1500 industrial technological line is a new word in technology of basalt processing it makes production process easy There is no need to build traditional plants for dear prices any more TE CBF 1000 1500 lines are the base of CBF production plants with production capacities 3 000 / 5 000 / 10 000 / 15 000 tons a year

الاستفسار عبر الإنترنت →

·The complete set of basalt sand production line with a daily output of 500 tons is used Large pieces of basalt are evenly fed into the jaw crusher by the feeder for preliminary crushing; then they are sent to the impact crusher/cone crusher by the

الاستفسار عبر الإنترنت →

·The manufacturing process of continuous basalt architectures with fireproof and thermal insulation performance includes the preparation and processing of composite filaments and two step PIP processes Fig 1 In view of the forming ability of an AM manipulator TPU was uniformly coated on the surface of continuous basalt fibers Fig 1

الاستفسار عبر الإنترنت →

Cast basalt pipes are manufactured using a process that involves melting raw basalt rock at a temperature of approximately 1 400°C 2 552°F and then casting it into pipe form using centrifugal force The resulting pipes are chemically inert exhibit high resistance to thermal shock and can be produced in a range of sizes and shapes

الاستفسار عبر الإنترنت →

Wet laid Process Basalt Fiber Veil Introducing our Basalt Fiber Veil meticulously crafted through the innovative wet laid process With exceptional durability and flexibility it s the ideal solution for various industrial applications offering reliability and performance where it

الاستفسار عبر الإنترنت →

Refining basalt to a finely crystallised glass ceramic Multotec s cast basalt wear resistant material provides an extremely durable long lasting lining for static plants bearing large volumes of abrasive and/or corrosive Supplied as both a pipe and tile lining solution cast basalt is ideally suited for wet material handling applications with lower impacts such

·There are several basalt processing plants in China These companies are specialized in providing a variety of mining and processing services for the basalt industry including crushing and

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.