في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·AusCrush has deployed Kleemann machines at the Peculiar Knob iron ore mine in South Australia leading to exceptional results MC0110PRO cone crusher secondary MSC953EVO classifying screen

·Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step from large pieces of raw iron ore about 500mm to millimeter level fine materials the structure is simple and the maintenance is simple and convenient However the discharge port of the fine jaw crusher can only be adjusted to a minimum of

الاستفسار عبر الإنترنت →

3 ·Common iron ore washing process The commonly used method of ore dressing in iron ore washing plants is gravity separation with low equipment value simple structure and simple and convenient maintenance However the minimum discharge opening of the fine jaw crusher can only be adjusted to 25mm so the crushing particle size is generally

الاستفسار عبر الإنترنت →

·When crushing use a jaw crusher for coarse crushing and then use a cone crusher for fine crushing When grinding use a ball mill or a rod mill As proper grinding fineness is crucial to the flotation results the particle size of titanium ore generally needs to be ground to less than mm for a better flotation effect

الاستفسار عبر الإنترنت →

·1 The raw magnetite ore is sent to the coarse crusher jaw crusher by the vibrating feeder and then sent to the fine crusher cone crusher or hammer crusher 2 After fine crushing the ore is sent to the screening machine The material under the sieve is qualified and sent to the next stage while the large particle material is returned to

الاستفسار عبر الإنترنت →

·Mastering jaw crusher maintenance skills is benefit to improve machine life span as well as production here you will learn how to change jaw plates repair and maintain other important parts contamination of the bearing is too high which is mainly reflected in the increase in oil and grease Such as iron content is higher than 150ppm

الاستفسار عبر الإنترنت →

·5 Gyratory crusher A gyratory crusher is similar in basic concept to a jaw crusher consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel

·A cone crusher is a powerful tool used in the mining aggregate and construction industries to crush materials into smaller pieces But how does it work In this article we ll explore the cone crusher working principle including the eccentric motion of the main shaft the crushing process and the importance of proper maintenance Whether

الاستفسار عبر الإنترنت →

·Simheuristic based decision support system for efficiency improvement of an iron ore crusher circuit Author links open In Section 3 the problem is defined In Section 4 the cone crusher efficiency is discussed in terms of the cavity level The simulation is presented in Section 5 This method can identify how many capacitors are

الاستفسار عبر الإنترنت →

·Standard Secondary Cone Crusher Refer to Fig 1 The Standard Cone crusher is normally applied as a secondary crusher in a multi stage crushing circuit The small diameter feed distributor and the wide throat opening at the top of the liners enable the Standard Cone crusher to accommodate the larger feed produced by the Primary crusher

الاستفسار عبر الإنترنت →

·The most commonly used stacking methods for making longitudinal stockpiles are Cone Shell Chevron and Windrow Basically these methods consist of stacking a large number of layers on top of each other in the longitudinal direction of the pile In the Cone Shell method the pile is formed by depositing material in a single cone from

الاستفسار عبر الإنترنت →

·Cone crushers Cone crushers are one of the main choices for secondary crushing A cone crusher is a powerful machine that is used in large scale industries for crushing various types of materials into smaller sizes It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force

الاستفسار عبر الإنترنت →

·A short head cone crusher has a short crushing chamber and it is designed for the production of finer output sizes generally between 6 mm and 25 mm A fine cone crusher also known as a tertiary cone crusher is used for the production of They are manufactured to produce very fine output sizes mostly below 6 mm

الاستفسار عبر الإنترنت →

·Last month Rio Tinto selected Metso to deliver ten HP Series cone crushers for installation at the Tom Price iron ore mine in Western Australia In August 2023 Mesto was selected by Rio Tinto for design and engineering work for a continuous pilot plant CPP for the BioIron A low carbon iron making process BioIron uses ore

الاستفسار عبر الإنترنت →

·The final stage in iron ore processing is ironmaking where the iron ore is transformed into molten iron through a process called reduction The most common method of ironmaking is the blast furnace route In a blast furnace iron ore coke carbon and fluxes limestone or dolomite are loaded into the furnace from the top

الاستفسار عبر الإنترنت →

·The size of the jaw crusher s discharge port determines the size of the ore after crushing and the production capacity of the equipment Due to wear and changes in the particle size requirements of the finished product it is necessary to adjust the s Cone Crusher; Impact Crusher; Sand Making Machine; News list Choose jaw crusher or

·Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step from large pieces of raw iron ore about 500mm to millimeter level fine materials the structure is simple and the maintenance is simple and convenient However the discharge port of the fine jaw crusher can only be adjusted to a minimum of

الاستفسار عبر الإنترنت →

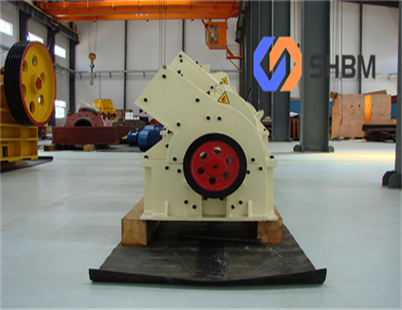

Cone crusher is used in mining road & rail construction It is mainly used as a secondary grinder because it is designed to grind hard or medium ore such as iron ore pebble limestone granite and basalt It is also used as a compression machine to reduce steel material size Final size is determined by the narrowest gap at the bottom

الاستفسار عبر الإنترنت →

2 ·Configuration vibrating feeder jaw crusher medium crushing compound cone crusher Finished vibrating screen Benefits of choosing this configuration 1 The excellent granularity of the finished product Excellent quality of the processed finished product which can be sold at a good price 2 Easy maintenance on site

الاستفسار عبر الإنترنت →

·AusCrush has deployed Kleemann machines at the Peculiar Knob iron ore mine in South Australia leading to exceptional results MC0110PRO cone crusher secondary MSC953EVO classifying screen

·While the cone crusher is more suitable for hard rocks and ores such as iron ore granite pebble Besides a cone crusher is not suitable for crushing viscous materials that contain a lot of moisture 5 Feeding requirements With a cone crusher the material can be fed directly into the machine until it s full and no silos and feeders are

الاستفسار عبر الإنترنت →

·Throughput capacity will vary depending on the type of material feed gradation moisture content chamber selection feed method and other site specific operating conditions 11 crusher capacities Open Circuit Crushing Capacities SBS Series Cone Crusher Model Total throughput at discharge setting CSS shown 3/8" 10 mm 1/2"

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.