في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all

الاستفسار عبر الإنترنت →

·Jaw crusher V type structure crushing chamber the actual feed port width is the same as the nominal feed port can meet the requirements of greater feeding higher crushing efficiency using toothed guard plate increase the effective length of the jaw plate to achieve the purpose of increasing output

·Types of Jaw Crushers There are two types of Jaw Crushers Single Toggle and Double Toggle Single Toggle The single toggle movement jaw crusher more compact than double toggle designs was once unable to accept large feed sizes However technological innovations have solved this issue making these machines popular for their

الاستفسار عبر الإنترنت →

·Straight Jaw Plates A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates This type of plate has been the standard from the time of its inception emulating in this respect the straight concaves in the gyratory machine And it will be noted that the theoretical action in this straight plate ="Jaw

الاستفسار عبر الإنترنت →

·Like the jaw crusher the cone crusher provides a relatively low cost crushing solution but there are application drawbacks that may make another crushing solution more appealing First cone crushers cannot accept all material sizes Any material fed to the crusher must be pre sized for that particular crusher usually 200mm or less

الاستفسار عبر الإنترنت →

·Flotation separation is the main method of separating lithium ore at present All lithium ore with industrial value can be enriched by flotation especially the fine grained disseminated lithium ore Flotation is done in an alkaline environment as it not only has a good flotation result but also protects the flotation machine and is easy to

الاستفسار عبر الإنترنت →

·Mine haul truck capacity is an important factor at primary crusher installations because it is cost effective to integrate truck cycle time at the crusher station with mine/shovel operations If a primary crusher dump pocket is undersized and unable to handle the mine s trucks then operators must slowly meter the ore into the receiving

الاستفسار عبر الإنترنت →

·Scalping is usually recommended before a jaw crusher whereas gyratory crushers can handle the excavated ore as is This is because primary gyratories are not as sensitive to fines they are large steep and have a relatively short stroke compared with settings that allow fines to flow through more easily

الاستفسار عبر الإنترنت →

2 ·For instance if the final size of your product only needs to be between 4 inches and 6 inches a primary jaw or impact crusher can accomplish your goals However you will likely require a much finer product and that means incorporating up to three—or even four—stations with a variety of crusher types 1 Primary Crushing

الاستفسار عبر الإنترنت →

·After mining the raw lithium ore is crushed through a jaw crusher and a cone crusher for two stage crushing Screening Then use a vibrating screen to sieve Qualified lithium ore enters the next grinding process Grinding/Milling The ore is wet ground by a ball mill into a particle size within mm Flotation and magnetic separation

According to the different types of equipment there are basically three ways to adjust the discharge opening of jaw crusher 1 Hydraulic adjustment The rear thrust plate is used as the safety device of the crusher Equipment required for

الاستفسار عبر الإنترنت →

·Positioned on the crushing chamber s walls jaw plates are the components directly involved in crushing They come in various shapes and sizes to accommodate different types of materials Pitman

الاستفسار عبر الإنترنت →

2 Both the structure and working of a jaw crusher are quite simple 3 The product size is quite small and can range up to millimetres 4 Repair and maintenance of a jaw crusher are convenient and easy 5 The reliability of a jaw crusher is significantly high 6 The broken parts of the jaw crusher are easy to replace Disadvantages of a Jaw

الاستفسار عبر الإنترنت →

As a professional stone crusher factory BANGDE has its casting workshop All castings can be produced by ourselves This can guarantee quality and fast delivery of worn and spare parts BANGDE is a stone crusher machine manufacturer providing the one stop solution We have a complete range of feeding crushing sand making and screening

الاستفسار عبر الإنترنت →

Types and Applications While there are many different kinds of jaw crushers on the market two types are predominantly used the single toggle jaw crusher and the double toggle jaw crusher Single toggle jaw crushers a seemingly simple yet complex mechanism have a swing jaw which moves in an elliptical path from the bottom to the top of the

الاستفسار عبر الإنترنت →

·The beneficiation and flotation process of lithium ore flotation technology mainly includes crushing grinding and Crushing is to change the large pieces of lithium ore into small pieces to meet the requirements of the following process for the particle size of lithium ore ; Grinding is to dissociate lithium ore from gangue minerals to the

الاستفسار عبر الإنترنت →

·The jaw crusher works by moving the material between a fixed and a moving plate The moving plate applies force to the material causing it to break down into smaller pieces The gyratory crusher on the other hand uses a mantle and concave surfaces to compress the material Jaw crushers are the most popular type of primary

الاستفسار عبر الإنترنت →

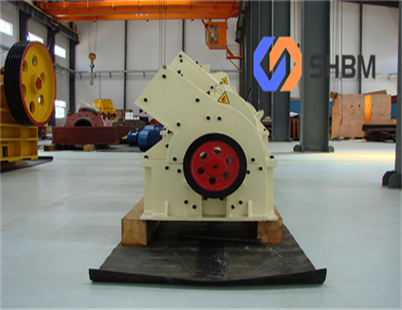

·As a green energy mineral the most common type of lithium ore is spodumene This blog will focus on spodumene analyze the processing technology and equipment of spodumene and how to make lithium carbonate Jaw crusher The raw ore enters the jaw crusher through the feeder for coarse crushing Minimum price $1 000

الاستفسار عبر الإنترنت →

·A jaw crusher may sound like some medieval torture device but they re not While they could be used to that effect they re more widely used in the areas of demolition and mining A jaw crusher essentially crushes large rocks to a more usable size Popular types of Jaw Crushers Double Toggle Blake Type or Overhead Pivot

الاستفسار عبر الإنترنت →

There are a variety of crushers that can be used in lithium ore processing The most common crusher types are jaw crushers cone crushers and impact crushers Jaw crushers are typically used for primary crushing while cone crushers and impact crushers are used for secondary and tertiary crushing

Using Jaw crusher in Primary Crushing In the primary crushing of iron ore we suggest you choose a jaw crusher This type of crusher is the most traditional and most reliable coarse crushing equipment and it has wide applications And its production process and technical level are very advanced

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.