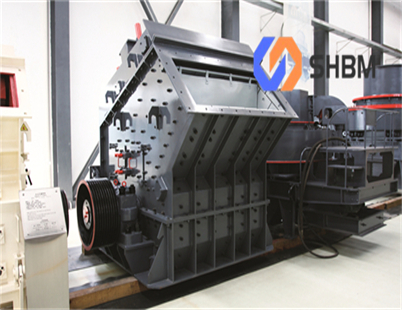

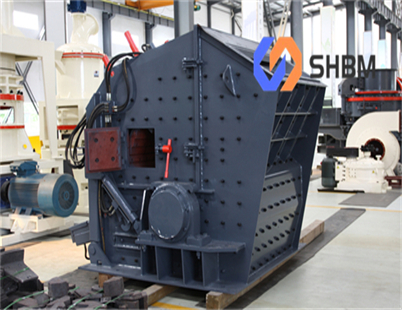

في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

Summary Much has been written researched and applied toward the advancement of improving gravel packing technology in the past 10 to 15 years Still gravel packing is not a routinely successful completion method to control sand production from weakly consolidated formations One of the principal reasons for this lack of consistency is an incomplete

الاستفسار عبر الإنترنت →

·A 2 or 3 foot thick layer of gravel should be installed over the drain tile This allows water to flow readily to the pipe and prevents clogging Avoid using sandy gravel as it can slow down water movement Another important factor is protecting the gravel layer and drain tile pipe from clogging This can be done by

Abstract The production of sand associated with oil and gas developments has been a considerable problem in production operations in the recent past Early investigative work on the subject concentrated upon the mechanisms by which sand production is initiated and in addition how the sand might be restrained from flow into the wellbore by a concentric

الاستفسار عبر الإنترنت →

·he success of gravel aggregate production line mainly depends on reasonable equipment selection which is generally determined by material hardness soil content and corrosivity index soil content and corrosivity index Some production line investors do not find formal design units or copy the equipment selection of other

الاستفسار عبر الإنترنت →

·However they can also transfer potable water to different islands The design of sub sea pipelines is very challenging as they are subjected to harsh subsea environments very high pressures and corrosive fluids Reduced Installation Time from remote exploration and production sites to processing facilities and ultimately

الاستفسار عبر الإنترنت →

·and borehole wall is filled with gravel or coarse sand called the gravel packor filter pack The gravel pack prevents sand and fine sand particles from moving from the aquifer forma tion into the well The gravel pack does not exclude fine silt and clay particles; where those occur in a formation it is best to use blank casing sections

·Download Citation Design of the Production Line Control System of Beverage Filling Based on PLC PLC control program is simple and easy to use reliable and so on In the field of industrial

الاستفسار عبر الإنترنت →

·Production of the sand becomes a significant problem throughout the life of wells especially in poorly consolidated reservoirs This issue frequently leads to tube buckling and abrasion of the

الاستفسار عبر الإنترنت →

·Gruesbeck et al 1979 established a gravel packing laboratory wellbore and described the gravel packing process in highly deviated wells through two kinds of wellbore experiments; put forward the concept of equilibrium bank for the first time Experimental results show that the equilibrium velocity decreases with decreasing

الاستفسار عبر الإنترنت →

·1 Details of the annual output of 7 million tons of construction stone tuff sand and gravel production line Usually the configuration of a complete building stone tuff sand production line

الاستفسار عبر الإنترنت →

·The process design balances the electricity water and gas consumption of the whole plant and uses the system theory to match the performance of each link of the machine made sand and gravel production line so that the entire production line runs with high quality and efficiency

الاستفسار عبر الإنترنت →

·Step 4 Implementation of the new aggregate production line When install ing a new production line every step has to be taken at the right time and in the right way However thorough our audits can t uncover every possible variable and we can experience unexpected issues with the existing foundation or machinery for example so we

الاستفسار عبر الإنترنت →

·Module 3 — Design and Construction of Water Wells Well Design Considerations Well design and construction details are determined after a test hole has been completed and the geological zones have been logged There are many components to well design the driller must take into account Decisions will be made about Type of

الاستفسار عبر الإنترنت →

·About 4 to 6 inches larger than the casing size is pretty common If you are working shallow say less than 100 feet it is common to pour the gravel from the top If you are much deeper the gravel must be pumped through a tremie line Usually the gravel is pumped with chlorinated clear water to remove the filter cake and displace the drill mud

الاستفسار عبر الإنترنت →

·MM HASAN LECTURER AIE HSTU The design of a tube well involves the following steps 1 Mechanical analysis of samples of the underground formation obtained from various depths and the preparation of a well log 2 Design of housing pipe and well casing 3 Design of well screen 4 Design of gravel pack 5 Design for sanitary protection

الاستفسار عبر الإنترنت →

·With proper design and installation gravel pack completions can yield optimum long term performance The best strategy should therefore involve a rational compromise between achieving optimum

الاستفسار عبر الإنترنت →

· Pipe Design and Installation 3/6/24 NM Version ACS Review Annual Contestability Reviewed No change 4/12/23 NM JA TP Version Materials receipts DWI Approval Number AND certificate of conformity 21 Schedule of Permissible Materials and Construction 26/9/23 NM Version

الاستفسار عبر الإنترنت →

·A Critical Review on Root Cause Analysis on Gravel Packing Design and Installation Issues by Farah Badrul Hisham 14999 Dissertation submitted in partial fulfilment of the requirements for the Among the problems that will occur are production losses erosion of hardware tubular blockage sand disposal issues and many more There are

الاستفسار عبر الإنترنت →

·GRAVEL SURFACES Design & installation guidance Note 1 A free draining Class 805 DoT Type 3 open graded reduced fines sub base is preferred especially where a SUDS Sustainable Urban Drainage System is proposed A low permeabilty Class 803 DoT Type 1 may be considered but an adequate and functioning

·A complete sand and gravel aggregate production line is compose of crushing system screening system sand production system there is no this system if customers do not need artificial sand storage and delivery system dust removal system Many customers wonder how to configure and design complete sand and gravel

الاستفسار عبر الإنترنت →

·Firstly the paper made the overall design of the automatic production line takt time is calculated according to the annual production demand and the analysis of device configuration and position layout of the production line was carried out based on the annual production requirement Secondly the paper selects types of CNC machines and

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.