في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·The process choice of copper ore flotation is determined by the raw ore properties Meanwhile there are many determining factors for the copper ore flotation process like the mineral disseminated particle size the associated relationship with quartz rock and the gangue mineral types

·The ore crushing process includes four types ore coarse crushing ore medium crushing ore fine crushing and ore superfine crushing Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500 1500 mm to 125 400 mm The maximum crushing ratio of coarse crushing is about three The main force in the

الاستفسار عبر الإنترنت →

·2 Screens Screens are used to separate manganese ore particles based on size ensuring that only the desired material is processed further Vibrating screens trommel screens and inclined screens are commonly used in manganese processing plants Screening machine 3

الاستفسار عبر الإنترنت →

·We own advanced cutting automatic welding and boring machine which make our crushing & screening machine of high quality and good appearance JXSC has been engaged in the production and sales of crushing & screening equipment since 1985 It is a professional China manufacturer of crushers and beneficiation equipment

الاستفسار عبر الإنترنت →

·stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing

·The ore crushing process includes four types ore coarse crushing ore medium crushing ore fine crushing and ore superfine crushing Ore coarse crushing is a process of crushing ore blocks with a feeding particle size of 500 1500 mm to 125 400 mm The maximum crushing ratio of coarse crushing is about three The main force in the

الاستفسار عبر الإنترنت →

1 ·JXSC manganese ore process and equipment can separate various components of ore including crushing washing screening gravity separation magnetic separation and flotation processes beneficiation the ore becomes more valuable and can be used in various industries such as steelmaking and alloys Application beneficiation of the

الاستفسار عبر الإنترنت →

·This article explains the characteristics of 8 kinds of commonly used screening machines and the screening equipment suitable for different processing stages in the sand and gravel production line Commonly used screening equipment mainly include vibrating screen fixed screen roller screen and so on 1 Fixed screen

الاستفسار عبر الإنترنت →

Plane type Copper wire Screening machine one stranding cage can load many bobbins 2 Wire Pay off bobbin available from Φ200 Φ500 3 The stranding cage and the taping heads are driven by individual motor stepless adjustable pitch 4 The center main shaft is a thick walled whole length of seamless steel tube not welded

الاستفسار عبر الإنترنت →

Then if multiple machines or crushing stages were required for a project the crushing station was still of an acceptable overall height Another major step in the crushing circuit for bauxite ore applications and nearly all crushing applications is the screening stage The screening stage separates particles in the material flow by their

الاستفسار عبر الإنترنت →

5 ·At Bellian Mining Machinery we specialize in crafting advanced solutions for ore crushing sand making and grinding processes Whether it s efficiently crushing ores creating high quality sand for construction or precision grinding for various applications Choose Bellian Mining Machinery for all your mining and processing needs where

الاستفسار عبر الإنترنت →

Portable rock crushing and screening plants built heavy duty to suit virtually any size job or aggregate feed material crushing coal or general mining applications View our JHT Jaw Rock Crusher Screen Machines Industries LLC 10685 Columbus Parkway Etna Ohio USA 43062 740 927 3464 Email

الاستفسار عبر الإنترنت →

Even though the ore is reduced below 3 mm with conical and some impact crushers this process is called crushing The process of size reduction is defined by below conversion formula The ore whose size will be reduced Energy = Reduced size ore Sound Heat

الاستفسار عبر الإنترنت →

6 ·The mobile crushing station is widely used in the crushing screening as well as the recycling of minerals stones and other aggregates basalt gabbro limestone cobblestone dolomite silica sand talc etc Mining crushing gold ore iron ore copper ore manganese ore lithium ore lead zinc ore coal etc We can design and

الاستفسار عبر الإنترنت →

·In addition to single machines in the stage parallel units must also be considered in order to reach the desired capacity The paper has the following outline It starts by describing the main design idea of crushing and screening plants It is important to understand the purposes of the different crushing stages in a crushing plant

الاستفسار عبر الإنترنت →

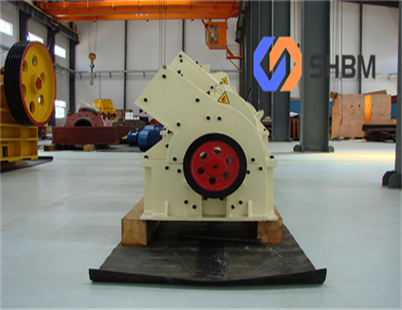

It is mainly used for crushing and grinding ore And it can crush all kinds of ores such as iron ore copper ore gold ore and so on Besides ore crushing machine can be widely used in mining smelting building material road railway water conservancy chemical industry and many other industries Classifications of Ore Crusher

الاستفسار عبر الإنترنت →

· The benefits of real time machine data flow and capture for operators is critical as they can make safe and informed decisions while undertaking a crushing and screening campaign

الاستفسار عبر الإنترنت →

·Manganese beneficiation machines are essential tools for efficient processing of manganese ores The top 10 machines discussed in this article including magnetic separators jig machines shaking tables hydrocyclones spiral classifiers flotation machines high intensity magnetic separators centrifugal concentrators magnetic

الاستفسار عبر الإنترنت →

4 ·Copper processing is a complicated process that begins with mining of the ore less than 1% copper and ends with sheets of % pure copper called cathodes which will ultimately be made into products for everyday most common types of ore copper oxide and copper sulfide undergo two different processes hydrometallurgy and

الاستفسار عبر الإنترنت →

·stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing

ore grinding tantalum Ore grinding tantalum ore grinding tantalum tantalum processing machine Ethiopia tantalum mining Tantalum mining is a comprehensive project which combines the tantalum ore crushing Copper mining processing copper grinding beneficiation for Copper Mining Process The traditional method used at Get Price; extec

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.