في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

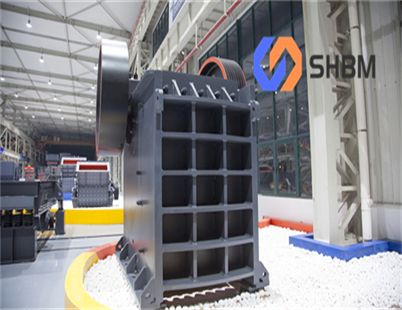

·Introduction Jaw crushers are powerful machines that are widely used in the mining quarrying and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further processing A jaw crusher consists of a fixed jaw and a movable jaw with the latter being driven by an eccentric shaft that moves the

الاستفسار عبر الإنترنت →

Jaw mobile crushing plant is also known as a coarse crushing tire mobile crushing station Therefore it is usually used for primary crushing small mobile jaw crusher plant adopts an integrated operation method which eliminates the installation of complex site infrastructure and auxiliary facilities The overall structure of the mobile jaw crushing

الاستفسار عبر الإنترنت →

·Jaw crushers are large scale heavy duty machinery typically constructed with cast iron and/or steel Often considered a basic machine jaw crushers have their place in the industry They are often used to reduce rock into non uniformed gravel To find out more about primary jaw crusher check out our blog Cross section of a Kleeman primary

الاستفسار عبر الإنترنت →

·The toggle plates are mounted on a pitman that is driven by an eccentric shaft The pitman is moved back and forth by the eccentric shaft which causes the toggle plates to move the swing jaw up and down Working Principle The Blake jaw crusher works on the principle of a toggle mechanism The swing jaw is moved back and forth by the

الاستفسار عبر الإنترنت →

Working Principle Jaw crushers reduce rocks or ore by means of mechanical pressure is achieved by the crusher s two jaw dies/ jaw plates one of which is stationary and the other is two vertical manganese jaw dies create a V shaped cavity called the crushing material is fed into the top of and the

الاستفسار عبر الإنترنت →

Gold Ore Milling Machine Manufacturer in China With Excellent Working Principle of Gold Ore Milling Machine Firstly raw material is crushed by jaw crusher to the size required then elevated into a hopper from which the

الاستفسار عبر الإنترنت →

A jaw or toggle crusher consists of a set of vertical jaws one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw moves back and forth relative to it by a cam or pitman mechanism acting like a class II lever or a nutcracker The volume or cavity between the two jaws is called the crushing chamber

الاستفسار عبر الإنترنت →

·Ore Jaw crusher is a device that uses the relative rotation of two jaw plates to crush materials to the required particle size under the action of extrusion shear and friction In iron ore crushing the working principle of jaw crusher is mainly reflected in the following steps 1 Motor drive The motor drives the eccentric shaft to rotate

الاستفسار عبر الإنترنت →

·3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing

الاستفسار عبر الإنترنت →

·To crush the of coal in a Primary Jaw Crusher Blake Jaw Crusher and determination of average product size by the use sieve shaker MATERIALS / APPARATUS REQUIRED 1 Coal 2 Different sieve screens of ASTM size 3 Black jaw crusher 4 Weight balance 5 Ro Tap sieve shaker THEORY Blake Jaw Crusher It has its moving jaw

The working principle of a jaw crusher is straightforward The crusher s mechanical components such as the eccentric shaft toggle plates and toggle seats allow for the continuous crushing motion and force that is generated when the crusher s two jaw plates are working in tandem Such as iron ore copper coal gold chrome ore zinc

الاستفسار عبر الإنترنت →

Gold ore crusher plays a crucial role in the gold mining industry particularly when it comes to crushing and extracting gold from the ore Jaw crushers are at the forefront of this process serving as reliable and efficient machines for breaking down large pieces of gold ore into smaller more manageable sizes

الاستفسار عبر الإنترنت →

·High quality Casting Ensures Reliable Performances In order to ensure stable and efficient production during crushing hard materials C6X Jaw Crusher is equipped with such core rotating components as high quality casting movable jaw body large eccentric heavy duty forged eccentric shaft cast flywheel with a high moment of inertia

الاستفسار عبر الإنترنت →

·Jaw crusher is used as primary crusher it s reduction ratio is usually 6 1 gyratory crusher working principle animation image credit by 911 Metallurgist Gold Trommel Gold Wash Plant Dense Media Separation System CIP CIL Ball Mill Trommel Scrubber Shaker Table Jig Concentrator Spiral Separator Slurry Pump Trommel

الاستفسار عبر الإنترنت →

·• Working Principle Of A Jaw Crusher • A jaw crusher uses compressive force for breaking of particle • A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw mounted in a "V" alignment is the stationary breaking surface while the movable jaw exerts force on the rock by forcing it against the

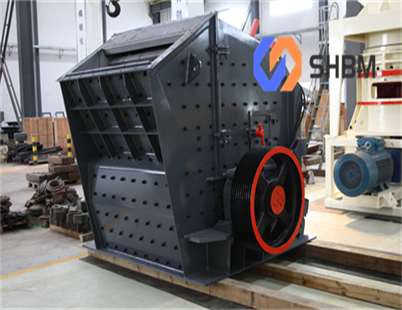

Like jaw crusher machine impact crusher for sale also has so many types such as PF1007 PF1010 PF1210 PF1214 PF1315 and so on Besides the impact crusher design is reasonable Different types of crushers have different input

الاستفسار عبر الإنترنت →

·We take a Φ900 x 900mm single rotor irreversible multi row hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone coal and other medium hardness ores It is mainly composed of a transmission device rotor lining

الاستفسار عبر الإنترنت →

·All types gold silver and portable ore bodies Combines mobility with high capacity suitable for mining operations with changing locations PEX / PE All types copper zinc small to medium gold ore bodies Good for precise size reduction in secondary/tertiary crushing stages

الاستفسار عبر الإنترنت →

·The processing capacity of the large jaw crusher has reached 1 500 tons per hour The working principle of the jaw crusher is as follows The movable jaw plate makes periodic reciprocating motions against the fixed jaw plate sometimes approaching and sometimes leaving

الاستفسار عبر الإنترنت →

·1 Jaw crusher The jaw crushers are popular primary crushers for coal They are often used in mines and quarries where large amounts of coal are mined The working principle of the jaw crusher is to use compression force to compress coal between a fixed jaw and a movable jaw for coarse crushing

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.