في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

Star trace is a professional crushing roll manufacturer in India which adopts advanced manufacturing equipment and technology to produce various crushing series of roll crusher mainly consist of roller the roller back up bearing compaction and adjusting device and actuating device The grain size is adjustable between two rollers equipped

الاستفسار عبر الإنترنت →

Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages the size reduction process performed with crushers before grinding in mills is called "crushing" Blade mill is designed to separate crush wash and clean aggregates and crushed stones

الاستفسار عبر الإنترنت →

The walls of the gyratory crusher s hopper are lined with V shaped pieces the mantle and the concave like a jaw crusher but shaped like a cone The ore is discharged through the smaller bottom output hole of the cone While the cone does not move an interior crushing movement is created by a revolving shaft on a vertical rod

الاستفسار عبر الإنترنت →

In the other crushers most of the reduction is done by the impact of stone against metal Customers operating old rebuilt or expanded plants often have problems with the shape of the product In these cases the addition of a Barmac VSI in the final crushing stage offers a solution to product shape problems

2 ·Stone crusher plants are equipment designed to crush stones or rocks into different sizes for various applications Application Quarry / Mining Ore / Construction Project ; Capacity 0 100 / 100 200/ 200 300/ 300 500/ 500 700/ 700 1000 TPH ; Output Sizes 0 5/ 5 10/ 10 20/ 20 40 mm etc Customized Output Size; Then let s look

الاستفسار عبر الإنترنت →

Ball Mills Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100 years They are proven workhorses with discharge mesh sizes from 40M to <200M

الاستفسار عبر الإنترنت →

·During the collision both the objects may be moving such as a cricket bat hitting a fast moving ball or only one object may be moving such as a rock being struck by hammer blows There are two types of impact gravity impact and dynamic impact Coal dropped onto a hard surface such as a steel plate is an example of gravity impact

الاستفسار عبر الإنترنت →

·Soft rocks like limestone require less force while hard materials like iron ore need more power to effectively break them down into smaller pieces Secondary Crushing The secondary rock crushing step is the most important of all rock crushing stages as it directly affects the product quality and size range This stage consists of two rolls

الاستفسار عبر الإنترنت →

·Quarries are of two different types the pit quarry and the bank quarry The pit quarry is one in which the stone is extracted from below the general level of the surrounding country and as a rule the stone is elevated to the crushing and treatment plant on the surface Some operations in limestone and granite are of this type

الاستفسار عبر الإنترنت →

The material is crushed when the moving crusher compresses it against the fixed types of equipment come with heavy duty and light versions that are built with stainless steel housings The eccentric shaft is made of high grade forged steel and the moving jaw comes in either cast steel or welded version

الاستفسار عبر الإنترنت →

·Wide application Suitable for both dry and wet crushing for materials with up to 15% moisture One time forming Eliminates the need for primary and secondary crushing reducing costs by approximately 40% Large feed opening Handles feed sizes up to 1000 mm making it ideal for coarse crushing Non clogging Designed to ensure

الاستفسار عبر الإنترنت →

2 ·Small Scale Mining For breaking down small amounts of ore Construction For on site crushing of small quantities of building materials Recycling For crushing small amounts of concrete asphalt or other materials Key Components Frame The main structure that supports all other components Fixed Jaw Plate The stationary jaw that

الاستفسار عبر الإنترنت →

Fault diagnosis of mechanical equipment in high energy consumption industries in China A review Yongjian Sun Xiaohong Wang in Mechanical Systems and Signal Processing 2023 Crusher Crusher is a widely used gravel machine which is mainly used in the crushing of granite limestone quartz and other stones The crusher can crush the stone

الاستفسار عبر الإنترنت →

·This paper describes the design and operation of a high pressure shear cell HPSC capable of pressing granular material against candidate wear surfaces at macroscopic pressures of up to 700 MPa

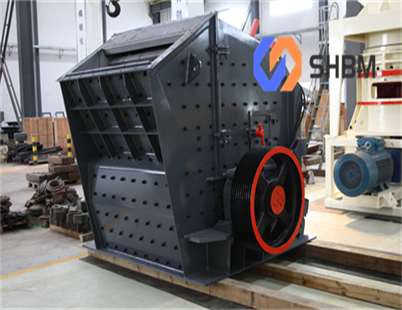

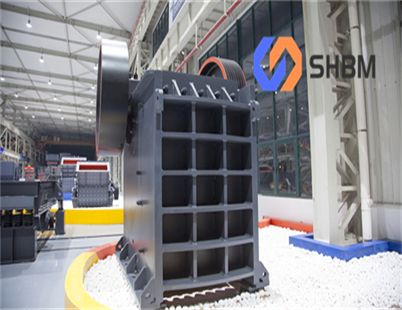

·Jaw Crushers feature a moving piece of steel called the pitman and a stationary piece of steel that form a V shaped chamber Material that enters the chamber is crushed to size between the moving piece of steel and the stationary piece of steel Most of the crushing action occurs in the bottom third of the chamber

الاستفسار عبر الإنترنت →

Mt Baker Mining and Metals is focused on providing a cost effective and durable ore processing plant that includes a jaw crusher hammer mill size classification equipment and sluice/shaker table This is the most efficient combination of cost productivity longevity and recovery when the job calls for processing bulk samples performing

·Crusher Clicker is an addictive game where you smash rocks and crystals then upgrade to enhance your crushing power and speed It's like operating a hydraulic press but with a satisfying stress relieving twist Boost your crusher's power speed and gravity for even more dramatic destruction Get lost in the colorful physics and the

الاستفسار عبر الإنترنت →

1 ·CJ series jaw crusher is a crushing equipment with advanced technology which has the advantages of small space occupation large crushing ratio and high processing capacity It is the best choice for large and medium sized stone production lines Maximum feed size ≤1 040 mm Discharge particle size 60 300 mm Capacity 105 1 280 t/h 4

الاستفسار عبر الإنترنت →

6 ·4 Crushing chamber The crushing chamber is an inverted cone shaped crushing space Its feed port is 15% larger than that of similar crushers and the feed size is as high as 1 350 mm The crushing cavity with a large inclination angle and long crushing surface design make the crusher have very high crushing efficiency

الاستفسار عبر الإنترنت →

·Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying are typically used as primary crushers to reduce large rocks ores and minerals into smaller more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency and this article will explore

الاستفسار عبر الإنترنت →

·STONE CRUSHING FOR AGGREGATES In the quarry industry ZENITH can help our customers crush lots of rocks such as granite basalt river stone and limestone and so on ZENITH solutions for aggregates are able to help them cut the cost reduce the risk and improve the quality of aggregates ZENITH specializes in the

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.