في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·Based on the mechanism used crushers are basically of three types; namely Cone crusher Jaw crusher and Impact Crusher The main objective is to design impact stone crusher

الاستفسار عبر الإنترنت →

·The working part of a jaw crusher consists of two jaw plates one is a fixed jaw plate fixed jaw which is vertically or slightly outwardly inclined at the upper end fixed to the front wall of the machine body and the other is a movable jaw plate movable jaw which is tilted in position and forms a crushing cavity working cavity

الاستفسار عبر الإنترنت →

·The high chromium alloy hammer is especially suitable for crushing high hardness materials such as quartz stone basalt etc However the traditional manufacturing process is complicated the process requirements are stricter and the price is higher How many types of jaw crusher with capacity and price 350 400TPH Complete Sand

الاستفسار عبر الإنترنت →

·An impact crusher can crush hard materials while a jaw crusher can crush brittle ones A jaw crusher is suitable to use for harder rocks such as granite basalt ores and concrete On the other hand an impact crusher will work best with clay limestone coal dolomite and other medium hardness materials

الاستفسار عبر الإنترنت →

·Dm›lŒ#B¡hýüôØ V7ó䫱÷6Ãyæß&æÑ;ô¶Öìå # ë7U X ¤ ;…&Å ˆG ÷Cõ—A Êï rùAq} Æ Øœ47 Jò ÙŒ¤f HÓibå s··ä ÔÉ Öö·½G%$&‚B È»mÿ»‰D„wwf¾Œ· j´½ ˜>$ ‡ û a=›Ê n† ß /# É ©¿ œ y}š xÔþÎÃzÖSÖٹνY±ü7Òæ[æË#L ® š]¼ Ê %‹bÄ£koÁðÃ

الاستفسار عبر الإنترنت →

·Jaw plates types from metso Standard XT710 and Super Grip XT710 Ideal for gravel and non abrasive rock crushing these types offer balanced power requirements and tooth spacing for fines removal resulting in less slabby product However they have a reduced lifetime in abrasive applications Quarry XT710 MX Suitable for

الاستفسار عبر الإنترنت →

4 ·This particular type of crusher is best suited for small batches because it requires less energy to breakdown the spodumene ore than other types of crushers Jaw Crusher is a more traditional type of crusher that has been used to produce all types of mineral products for over 100 years Jaw Crushers use ahammering action to break down rocks

الاستفسار عبر الإنترنت →

4 ·Processing capacity up to 200tph Configurations 200Kw impact crusher 1536 type return screen Maximum feeding 350 medium soft rock Crushing materials medium and soft rock and construction waste Applications construction aggregate or road construction Each module is compact and efficient hydraulic assisted in many places with return

2 ·A variety of models are available Get the free price list Capacity 20 800 t/h customized Max Feeding Size 130 mm 1000 mm; According to Model Motor Power 220 kw; According to Model Description Standard jaw crusher output particle size is large usually 100 350 mm and secondary crushing is required; It can directly process bulk

الاستفسار عبر الإنترنت →

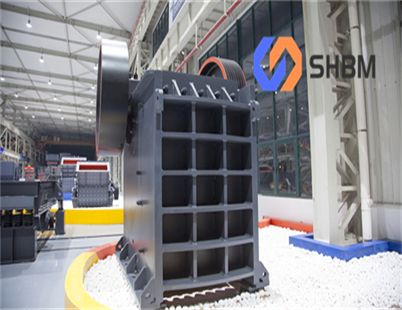

Jaw crushers are a type of crusher with a unique system Jaw crusher which is a very strong type of crusher performs the crushing process with the help of two plates One of these plates works by making constant the other by making elliptical movements The stones are shattered by the pressure exerted by these two jaws The principle of jaw

الاستفسار عبر الإنترنت →

It is a type of jaw crusher mounted on a fixed body and its jaw is made of sheet metal There are models of different strengths and sizes It is suitable for crushing hard and abrasive materials with high silica content such as basalt and granite Their production capacity is quite high It can easily process hard rocks Therefore

3 ·C5X Jaw Crusher The C5X Jaw Crusher features a well designed crushing chamber and outstanding motion characteristics boasting a larger stroke and higher speed that enhance the crushing efficiency The wedge type discharge port adjustment represents a mature method in the current market When adjusting the discharge port

الاستفسار عبر الإنترنت →

·Table Source Wikipedia Crushers Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface referred to as the mantle and the crusher bowl crushers are very similar to cone crushers but have a steeper cone slope and a concave bowl surface As the gap

الاستفسار عبر الإنترنت →

·A jaw crusher has a rectangular or square shaped opening at the top while a gyratory crusher has a conical shaped opening Furthermore the jaw crusher has a fixed jaw and a moving jaw whereas the gyratory crusher has a fixed central cone and a rotating mantle Consider design variations impact on crusher suitability for specific applications

الاستفسار عبر الإنترنت →

·It is a durable material that can withstand the high pressures and forces applied by a jaw crusher 2 Basalt This is another hard igneous rock that is commonly used in construction and building

الاستفسار عبر الإنترنت →

·There are 4 kinds of stone crusher machines fixed and mobile type semi fixed and semi mobile type The post will introduce their advantages and disadvantages stone crusher machines also called mobile or portable crushing plant are generally composed of crushers jaw crusher machine impact rock crusher hammer crusher cone

الاستفسار عبر الإنترنت →

·The jaw crusher is the most common type of primary crusher used in mining and quarrying operations It has a simple design reliable performance and high crushing ratio and size of the materials For hard and abrasive materials such as granite basalt and quartz a jaw crusher or gyratory crusher is preferred as the primary crusher

الاستفسار عبر الإنترنت →

WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER / JAW CRUSHER TYPES There are two main groups of jaw crushers categorized according to their jaw movement mechanism Single toggle jaw crushers Double toggle jaw crushers In single toggle jaw crushers the movable jaw is supported by the bearing on an eccentric shaft driven by the

الاستفسار عبر الإنترنت →

·The processing of basalt is divided into coarse crushing by jaw crusher medium and fine crushing by impact crusher/cone crusher as well as sand making and shaping by sand making machine At present there are two main types of basalt sand making equipment on the market namely VSI sand making machine vertical shaft impact

الاستفسار عبر الإنترنت →

·Introduction Jaw crushers are powerful machines that are widely used in the mining quarrying and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further processing A jaw crusher consists of a fixed jaw and a movable jaw with the latter being driven by an eccentric shaft that moves the

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.