في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·To achieve a model using physical modelling techniques the machine of interest a jaw crusher in this case has to be broken down into smaller subsystems and modelled separately for example breakage dynamics or pressure as seen in Fig this research the modelling approach is similar to the approach used by Evertsson 2000

الاستفسار عبر الإنترنت →

·Cleary [41] presented DEM models of an industrial scale jaw crusher and a VSI using the particle replacement model and spherical particles Lichter et al [59] introduced a Fast Breakage Geometry model parameters and operating conditions A cone crusher consists of a mantle or cone which is a precessing conical shaped structure

الاستفسار عبر الإنترنت →

·Figure 14 JKSimMet screen shot Data on the power draw and crusher energy is entered 31 Figure 15 JKSimMet screen shot Comparison of plant and JKSimMet generated data 32 Figure 16 Diagram to illustrate decking in blastholes 36 Figure 17 Cross section of a gyratory crusher 40 Figure 18 Cross section of a jaw crusher 40

الاستفسار عبر الإنترنت →

·The plate dimensions of the un optimised jaw crusher were modelled using ANSYS Design Modeller 2021 as shown in Fig load and boundary conditions for the static structural analysis were as shown in Fig of Experiments DoE was then conducted where the minimum and maximum values of the target parameters were

Cavity kinematics and operating parameters have been defined and optimized to ensure the outstanding performance for which Nordberg® C Series jaw crushers are known and valued Crusher height gives the steepest possible cavity cross section and the nip angle high up in the cavity together with an aggressive well aligned stroke at the

الاستفسار عبر الإنترنت →

·As an indirect jaw crushing parameter the choke feeding intensity was also emphasized by Beloglazov and Ikonnikov [40] As the rock comminution and energy efficiency can be defined as a function of area increment of particles in jaw crusher [41] the production of fines can be diminished by regulating the mf in the crushing chamber

الاستفسار عبر الإنترنت →

Introduction of barite grinding equipment Barite grinding equipment includes HGM ultrafine grinding mill jaw crusher bucket elevator electromagnetic vibrating feeder analyzer piping device blower silo power distribution cabinet etc equipment

Cavity kinematics and operating parameters have been defined and optimized to ensure the outstanding performance for which Nordberg® C Series jaw crushers are known and valued Crusher height gives the steepest possible cavity cross section and the nip angle high up in the cavity together with an aggressive well aligned stroke at the

الاستفسار عبر الإنترنت →

·A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

الاستفسار عبر الإنترنت →

·The actual minimum safe closed side setting of a crusher will vary somewhat for any given crushing machine depending upon the character of the material the amount of fines in the feed and whether the crusher is being operated under choke feed or regulated feed conditions It is possible when all conditions are favourable to operate

الاستفسار عبر الإنترنت →

·The plate dimensions of the un optimised jaw crusher were modelled using ANSYS Design Modeller 2021 as shown in Fig load and boundary conditions for the static structural analysis were as shown in Fig of Experiments DoE was then conducted where the minimum and maximum values of the target parameters were

·industrial applications with up to 11 000 jaw crusher installations since 1975 Developed to crush the hardest ores and rocks jaw crushers also perform outstandingly with less demanding materials In addition to the stationary jaw crushers many models are also available as mobile or portable versions Nordberg® C Series Proven

الاستفسار عبر الإنترنت →

·Model PE jaw crusher 400 600 Capacity 16 64 t/h Feeding size Size of final grain 40 100mm Rotor speed 280 300 rpm Main types and parameters Model FTM938HD86 FTM1149HD98 FTM1349HD110 FTM1349HD125 Transportation Length mm 12600 13500 14500 15200

·Such crushers are promising for use in mines to crush rocks laid in the developed space Mathematical modeling and optimization of the design parameters of the working chamber and the executive body roll of a single roll gyratory shaft crusher designed for crushing strong rocks was performed in this paper A differential equation

الاستفسار عبر الإنترنت →

·Available in four sizes as a light or heavy duty model they achieve throughputs of 250 t/h to 1 400 t/h The single toggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1 with new crushing elements 2

الاستفسار عبر الإنترنت →

·The article discusses the tests and calibration of material parameters and proceeds to test a breakage model in a laboratory scale jaw crusher The results are finally validated with the data from

الاستفسار عبر الإنترنت →

·The parameters within the models are parameters with units and have real physical meaning; for example a dimension of the machine The topic of control modeling focuses on how to apply the

الاستفسار عبر الإنترنت →

·Every PE Jaw Crusher was to precise processed to guarantee the eccentric shaft to possess sufficient strength and rigidity Precise blanking can guarantee the weights and structures of flywheel and grooved enhancing the operating balance Product pictures and parameters about models data performances and specifications on this website are

الاستفسار عبر الإنترنت →

PE1200 × 1500 Jaw Crusher PE 1200 × 1500 jaw crusher rack bit modular welded structure production capacity is between 500 800 tons per hour in large mines yield ore crushing demand material into the mouth of the size of 1200 × 1500 mm allows the maximum feed size is 1020 mm the discharge opening to allow adjustment range of 150 300 mm

الاستفسار عبر الإنترنت →

·Measurement of the electricity consumption during crushing was done on a laboratory jaw crusher Bauknecht Fig 1 Jaw crusher operates by compressing the feed material between a fixed and a moving jaw back and forth in an eccentric cyclic motion Cleary and Sinnott 2015 The feed size of the opening was 110 × 100 mm 2

الاستفسار عبر الإنترنت →

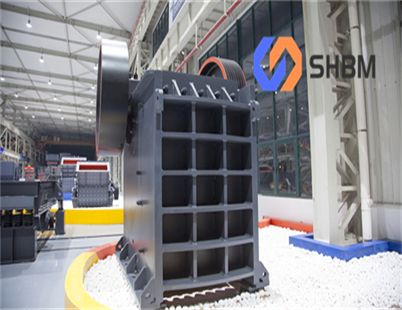

Crushers Barry A Wills James A Finch FRSC FCIM in Wills Mineral Processing Technology Eighth Edition 2016 Jaw crusher Construction Jaw crushers are heavy duty machines and hence must be robustly constructed The main frame is often made from cast iron or steel connected with tie bolts It is commonly made in sections so that it can be

الاستفسار عبر الإنترنت →

Sandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications Equipped with a C12 jaw crusher a powerful and fuel efficient engine it is designed to tackle the most difficult operations Full PLC control system and Danfoss color screen allow visual data output of all plant operating parameters This combined

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.