في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·• Crusher working benefits • Maintenance benefits NP1415 NP1620 NP2023 Secondary range The principle consists in positionning the Impact crusher capacity charts are developed for use as an application tool to properly utilize the NP impact crusher s capabilities The capacity

الاستفسار عبر الإنترنت →

The basic principle is straightforward the material to be crushed the feed drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motion The Sandvik CH cone crusher can be calibrated to achieve specific results maximize productivity and minimize wear but any calculation will be undermined without a

الاستفسار عبر الإنترنت →

Crusher Types There are three common crushers used at mining and processing plants Gyratory Crushers; Jaw Crushers; Cone Crushers; Typically the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed and this will be referred to as the Primary

الاستفسار عبر الإنترنت →

·1 Structure and Working Principle Jaw Crusher Jaw crushers have a fixed jaw plate and a movable jaw plate The movable jaw plate moves back and forth against the fixed jaw plate crushing the material by compressing it between the two plates Impact Crusher Impact crushers consist of a rotor with hammers or blow bars that spin at

الاستفسار عبر الإنترنت →

·Vertical shaft impact crusher VSI is also called sand making machine and it has become the main equipment of sand industry VSI crusher is used in sand quarry mixing station dry mortar quartz sand construction waste crushing industries and provide the high quality sand aggregate for highway railway construction municipal

2 ·Explanation The hammer mill uses the principle of impact and attrition operations for size reduction while jaw and rod mill are based on the compression techniques 5 Hammer mill has usually has hammers pinned

الاستفسار عبر الإنترنت →

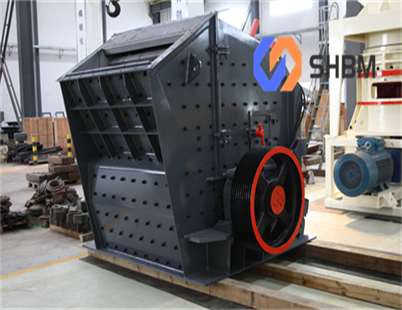

1 ·Working Principle of Impact Crusher Impact crusher is a kind of crushing machinery that uses impact energy to break materials When the crusher machine for sale is working on the motion of the motor the rotor began to spin at high speed Then the hard rock counter attacking crusher works and the electric motor drives the rotor where

الاستفسار عبر الإنترنت →

·Application of Impact Crusher limestone granite quarry stones rocks aggregate basalt gold ore iron ore etc final output size 0 10mm 10 20mm 20 30mm 30 40mm etc Working Principle Electrical motor drives through V belts and makes the rotor run at high speed Materials will be fed into the crushing

الاستفسار عبر الإنترنت →

·Stone crusher machines are essential tools in the construction industry used to crush rocks and stones into smaller pieces for a variety of applications This guide provides an overview of stone crusher machines including their history components applications and buying considerations Whether you are a contractor landscaper or

الاستفسار عبر الإنترنت →

·Crushers are mainly of three categories Cone crusher Jaw crusher and Impact crusher However there are few studies about the influence of crushers mechanism like jaw crusher horizontal shaft impactor and vertical shaft impactor Key Words comminution crushing principle reduction ratio type of crusher Effective circuits of

الاستفسار عبر الإنترنت →

·Mobile crushing plants have revolutionized the way materials are extracted and processed in various industries They offer flexibility mobility and efficiency that cannot be achieved with traditional stationary crushing plants As the name suggests these plants are designed to be easily moved from one site to another making them ideal for use in

الاستفسار عبر الإنترنت →

·4 Working principle 1 Jaw crusher The motor drives the belt and pulley to move the jaw up and down through an eccentric shaft When the moving jaw rises the angle between the toggle plate and the moving jaw increases thus pushing the moving jaw plate closer to the fixed jaw plate

الاستفسار عبر الإنترنت →

·Vertical Shaft Impact VSI crusher also know as a sand making machine which is a type of impact crusher that utilizes a high speed rotor with wear resistant tips to crush and shape the aggregate or rock fed into the machine English; Русский; Español Key Features and Working Principles of VSI Crusher 1 Rotor and Crushing Chamber

الاستفسار عبر الإنترنت →

·Basic Construction and Working Principle Horizontal Shaft Impact crusher consist of a hopper two or three aprons a rotor and blow bars or hammers Basically large products are fed into the hopper where they come into contact with hammers or blow bars to a spinning rotor which crushes the material into smaller pieces

الاستفسار عبر الإنترنت →

·Gyratory cone crushers are powerful machines that have revolutionized the crushing industry Their unique design and superior performance make them a popular choice for a wide range of applications from mining and construction to recycling and chemical processing In this article we explore the many advantages of gyratory cone

الاستفسار عبر الإنترنت →

An Insight into the Working Mechanism An impact crusher primarily relies on the force of impact to crush materials Its principle of working is strikingly different from jaw and cone crushers that utilize compression to break down materials In an impact crusher when the materials enter the blow bar area they get hit by the high speed

الاستفسار عبر الإنترنت →

·The obvious difference between jaw crusher and impact crusher is structure and working principle when choosing crushing equipment we should configure it reasonably according to production requirements in

الاستفسار عبر الإنترنت →

Impact Crusher Working Principle In the working process of the machine the rotor rotates at a high speed driven by the motor When materials enter the crushing chamber they will be impacted and crushed by the blow bar on the rapidly turning rotor and then thrown to the impact plate for a secondary breaking finally rebounded back to the

الاستفسار عبر الإنترنت →

·Impact crusher makes a very simple flow chart of crushing material Impact crusher has an ability to crush hard rocks It has high efficiency Easy hydraulic operation Working principle of vertical shaft impactor is totally different than horizontal shaft impactor It has a high speed rotor with wearing resistant tips and main chamber

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.