في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·If you are using a dump pit that uses a conveyor to feed the crusher then a metal detector and tramp magnet might work Oberfuhrer 9 years ago Oberfuhrer 9 years ago steel parts are being transported along with the ore boulders and directly unloaded to the primary crusher s gyratory or jaw crusher receiving chute

الاستفسار عبر الإنترنت →

·The jaw crusher has a simple structure is easy to manufacture reliable in operation and convenient to use and maintain The fineness of the jaw crusher can be varied from 10mm to 105mm and it can be adjusted according to customers needs Jaw crusher prices vary according to model and production capacity

الاستفسار عبر الإنترنت →

·In the single toggle jaw crusher an eccentric shaft is on the top of the crusher Shaft rotation along with the toggle plate causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher while the other is an eccentric shaft that drives both toggle

الاستفسار عبر الإنترنت →

1 ·Recycling on site demolition and construction waste is a cost efficient method of avoiding large landfill costs onsite recycling and reducing demolition rubble to a useable product The K JC 604 a 23in x 16in jaw crusher fitted with an integrated vibrating feeder the material to be processed is moved in a fast constant linear action into a jaw

الاستفسار عبر الإنترنت →

2 ·Capacity 1 1120t/h Configuration feeder jaw crusher belt conveyor Applicable Materials quartz granite basalt limestone cobblestone iron ore copper ore dolomite calcite etc Process The feeder quietly but efficiently supplies a steady stream of raw material to the primary function of a jaw crusher is to crush large rocks into

·Ore fine crushing is a process of crushing ore blocks with a feeding particle size of 50 150 mm to 5 25 mm and the maximum crushing ratio of fine crushing is about five The main equipment suitable for fine crushing operations includes a fine crushing jaw crusher short head cone crusher high pressure roller mill etc Ore superfine crushing

الاستفسار عبر الإنترنت →

·Exploring types of jaw crusher for mineral processing solutions Find out which one suits your needs on our informative blog Equipment If it weren t for the strong crushing power of jaw crushers getting minerals out of ore would be way more of a hassle really showing just how crucial they are to the whole industry

الاستفسار عبر الإنترنت →

·The Jaw Crusher is a improved Crafting Table that is used to crush rocks and ore Compared to the Stamp Mill it halves the crafting time and labor cost for all recipes Jaw Crusher x1 Steel Bar x25 Synthetic Rubber x25 Steel Gear x20 Electric Motor x2 Electronics Level 2 5 1200 5

الاستفسار عبر الإنترنت →

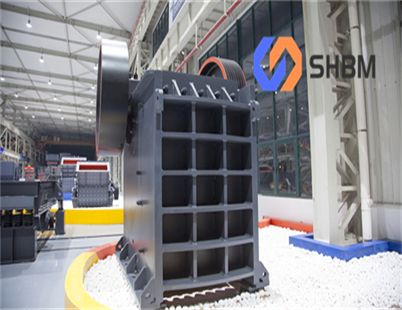

Crushers Barry A Wills James A Finch FRSC FCIM in Wills Mineral Processing Technology Eighth Edition 2016 Jaw crusher Construction Jaw crushers are heavy duty machines and hence must be robustly constructed The main frame is often made from cast iron or steel connected with tie bolts It is commonly made in sections so that it can be

الاستفسار عبر الإنترنت →

·The pin is 2 1/2 IN solid round stock The knuckle is a 2 1/2 section of well casing The jaw will be welded to the knuckle and will pivot around the pin So the bottom of the jaw seen in this pix will travel an arc as the other end of the jaw rides on the eccentric shaft A small arc but an arc nonetheless

الاستفسار عبر الإنترنت →

2 ·Capacity 1 1120t/h Configuration feeder jaw crusher belt conveyor Applicable Materials quartz granite basalt limestone cobblestone iron ore copper ore dolomite calcite etc Process The feeder quietly but efficiently supplies a steady stream of raw material to the primary function of a jaw crusher is to crush large rocks into

Jaw crushers are the workhorse of the crushing industry for mining construction and demolition recycling Mt Baker Mining and Metals jaw crushers are industrial grade continuous duty machines They take large pieces of rock ore concrete or other materials and crush them down to smaller sizes for further processing in a ball mill or hammer mill

الاستفسار عبر الإنترنت →

·PEW Jaw Crusher adopts V typed crushing chamber and tooth plate and helps to avoid material piling expand crushing space and improving crushing efficiency 0 720mm Capacity 150 500TPH Applicable Material Granite marble basalt limestone quartz pebble copper ore iron ore Technical Consultation Advantages Cases

الاستفسار عبر الإنترنت →

·Reading Time 6 minutes The jaw crusher is a reliable machine used in mining and construction Its importance to the building sector cannot be overemphasized This strong device is essential for reducing big rocks into smaller easier to handle chunks In this post we ll examine the…

الاستفسار عبر الإنترنت →

· Flyer The fault is mainly manifested in the large cone crusher rotating speed abnormality Flying car the crushed ore can not be discharged in time to form a blockage the crusher overloaded operation instant vibration is intense the working current increases steeply the temperature of the oil back to the surge the inertial impact

الاستفسار عبر الإنترنت →

1 20tph Mining PE 150X250 250X400 Used Diesel Engine Portable Mobile Small Mini Rock Stone Breaking Jaw Crusher Price for Ore Fine Crushing Machine Equipment US$ 2750 / Set 1 Set MOQ Zhengzhou Zhongjia Heavy Industry Co Ltd High Manganese Steel 1 / 6 Favorites Pyb600 Pyd600 Pyb900 High Quality Mini Rock Stone Spring Cone

الاستفسار عبر الإنترنت →

·A double toggle jaw crusher is a type of jaw crusher where the moving jaw is suspended from an eccentric shaft that is positioned on the top of the crusher The swing jaw is moved by a cam or pitman mechanism acting like a lever Jaw crushers are used to crush and reduce the size of various materials including rock and ore They work by

الاستفسار عبر الإنترنت →

·Mining Crusher Types Jaw Gyratory Cone Impact Hammer and More Processing; Mining Crusher Types Jaw Gyratory Cone Impact Hammer and More AllMinings 4 months ago 3 weeks ago 0 46 mins Subscribe to continue reading Subscribe to get access to the rest of this post and other subscriber only content

الاستفسار عبر الإنترنت →

·In the history of crushers both chronologically and by virtue of its standing in the field of heavy duty crushing the Blake jaw crusher stands first in the list All of the large heavy duty primary crushers of the jaw type are built around the Blake principle which for simplicity and brute strength is unsurpassed by any mechanism thus far devised for

الاستفسار عبر الإنترنت →

·Introduction Jaw crushers are powerful machines that are widely used in the mining quarrying and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further processing A jaw crusher consists of a fixed jaw and a movable jaw with the latter being driven by an eccentric shaft that moves the

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.