في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

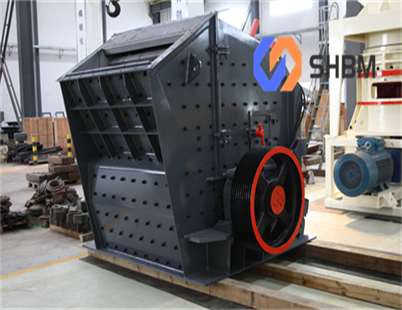

·The basic working principle of an impact crusher The fundamental working principle of an impact crusher is fairly straightforward yet its impact force can be substantial The machine crushes materials by applying a high speed impact force causing them to break into smaller pieces

الاستفسار عبر الإنترنت →

·Working principle of jaw crusher 1 The movable PE Series Jaw Crusher goes upward and downward through eccentric shaft when belt wheel are driven by the motor 2 The angle between PE Series Jaw Crusher and bracket turns big when the PE Series Jaw Crusher goes upward which pushes the PE Series Jaw Crusher plate to come

الاستفسار عبر الإنترنت →

·This is because the Blake Jaw Crusher integrated a key mechanical principle the toggle linkage a concept students of mechanics are familiar with Impact crushers have a very similar working principle except instead of the rotating parts hitting the material like a hammer they instead throw the material against an impact plate which

الاستفسار عبر الإنترنت →

·The working principle of a jaw crusher can be explained as follows Feed Hopper The large rocks or ore are fed into the jaw crusher through the feed hopper

الاستفسار عبر الإنترنت →

·The toggle plates are mounted on a pitman that is driven by an eccentric shaft The pitman is moved back and forth by the eccentric shaft which causes the toggle plates to move the swing jaw up and down Working Principle The Blake jaw crusher works on the principle of a toggle mechanism The swing jaw is moved back and forth by the

الاستفسار عبر الإنترنت →

·1 Working principle 2 Structure Let s dive right in 1 Working Principle of Rod Mill Rod mill is a common equipment for grinding operation in mineral concentrator which is mainly suitable for rough grinding operation

الاستفسار عبر الإنترنت →

·In this comprehensive guide we delve into the basics of jaw crushers shedding light on their structure working principles and diverse applications across industries Structure of Jaw Crushers

الاستفسار عبر الإنترنت →

·Second Jaw Crusher working principle use high speed rotating impeller stirring cans long tear break high speed about 1000 rpm / min of a series of multi piece spindle round steel circular

الاستفسار عبر الإنترنت →

2 ·Jig separator jig concentrator jig machine is a mining gravity separation equipment that drives pulses of water upwards through a thick bed of settled sediment to keep it loose and agitated This achieves gravitational separation by allowing the denser minerals to sink easily and quickly through the lighter minerals Jig separator are widely

6 ·ZSW Vibrating Feeder Features 1 Designed with extra heavy exciter and rack soundstructure strong anti impact capacity; 2 Perfect structure design high throughout capacity good material fluidity without blocking ; 3 Adjustable rod structure at the discharge end withprescreen performance; self lubrication omniseal exciter is convenient for

الاستفسار عبر الإنترنت →

·The processing capacity of the large jaw crusher has reached 1 500 tons per hour The working principle of the jaw crusher is as follows The movable jaw plate makes periodic reciprocating motions against the fixed jaw plate sometimes approaching and sometimes leaving

الاستفسار عبر الإنترنت →

Jaw Crusher Technical Details; Bag Filter Working Principle; Coal Crusher Glass Aggregate Systems For Sale; Roll Mill Saudi Arabia Waste Glass; HGM 125 pulverizer machine is the biggest type pulverizer rectorite diatomite barite gypsum alunite graphite fluorite rock After crushed by

الاستفسار عبر الإنترنت →

·The Zoneding Mobile Jaw Crusher is a robust and efficient machine designed for various materials and applications Here are some key specifications Applied Materials River pebbles granite basalt limestone construction waste bluestone and more ; Feed Size 400 1200mm; Capacity 85 650TPH; These specifications highlight the

الاستفسار عبر الإنترنت →

2 ·Jig separator jig concentrator jig machine is a mining gravity separation equipment that drives pulses of water upwards through a thick bed of settled sediment to keep it loose and agitated This achieves gravitational separation by allowing the denser minerals to sink easily and quickly through the lighter minerals Jig separator are widely

· Flyer The fault is mainly manifested in the large cone crusher rotating speed abnormality Flying car the crushed ore can not be discharged in time to form a blockage the crusher overloaded operation instant vibration is intense the working current increases steeply the temperature of the oil back to the surge the inertial impact

الاستفسار عبر الإنترنت →

·Jaw Crusher Working Principle The working principal of Jaw Crusher is based on modern design "CRUCHING WITHOUT RUBBING" The machine consists two Jaws one fixed and the other moving The opening between them is smaller at the bottom and wider at the top The pitman moving on an eccentric shaft on

الاستفسار عبر الإنترنت →

·Introduction of PE Jaw Crusher PE jaw crusher is mainly used in metallurgy mining chemical industry cement construction refractory materials and ceramics etc suitable for crushing hard ore and soft ore with compressive strength less than 320MPa The machine can break the material into medium size and fine size

2 ·Explanation The hammer mill uses the principle of impact and attrition operations for size reduction while jaw and rod mill are based on the compression techniques 5 Hammer mill has usually has hammers pinned

الاستفسار عبر الإنترنت →

·Working principle of phosphate ball mill The raw phosphorus ore is crushed to a Fluorite ball mills are widely used in fluorite beneficiation projects to grind fluorite ore into powder meeting the required specifications for various applications CRUSHING AND SCREENING Determine the particle size of lead zinc ore by crushing and

الاستفسار عبر الإنترنت →

2 ·Explanation The hammer mill uses the principle of impact and attrition operations for size reduction while jaw and rod mill are based on the compression techniques 5 Hammer mill has usually has hammers pinned

الاستفسار عبر الإنترنت →

·• Variable crushing jaw kinematics for higher fi nal fi neness Extra powerful premium pre crushing The most powerful FRITSCH Jaw Crusher ever up to 3 kW drive power ensure an exceptionally high throughput during pre crushing of hard or very hard brittle materials For easy cleaning the crushing jaws can be completely swivelled

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.