في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

This crusher is suitable for a wide range of tasks including high capacity secondary application and high reduction tertiary or pebble crushing application Sandvik CH420 cone crusher is of advanced design with a small footprint and high capacity in relation to size It has high reduction efficiency and is engineered to give optimal product

·Cone crusher is the secondary crushing equipment to crush the river pebble into required sizes for sand making Vibrating screen is used to separate the particles discharged from cone crusher and send the large ones back to cone crusher for re crushing The pebble is always processed into artificial sand materials for the construction application

الاستفسار عبر الإنترنت →

·In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics will be

الاستفسار عبر الإنترنت →

·Crusher type Cone crusher hydraulically adjusted Application Minerals processing Crushing stage Secondary Tertiary quartenary pebble Max feed size 275 mm 100 mm CSS range 13 51 mm 8 44 mm Nominal capacity 214 1 024 mtph 127 560 mtph Ambient temperature 20°C to 40°C Contact Sandvik if outside range Altitude of site ≤

الاستفسار عبر الإنترنت →

·Raptor® cone crushers 3 Reliable Rock solid performance Our Raptor cone crusher spare parts are designed to offer excellent performance with increased durability smoother operation and reduced maintenance expenses We keep your essential equipment running Structural Integrity The critical load bearing components of

الاستفسار عبر الإنترنت →

·A scheduled maintenance plan can keep major damage costs down and ensure your machines keep running efficiently through regular inspection Keep a log of maintenance checks to ensure they are completed on time Maintenance Tips for Crushers Jaw Crushers Check oil regularly making sure it is free of dirt and contaminants

الاستفسار عبر الإنترنت →

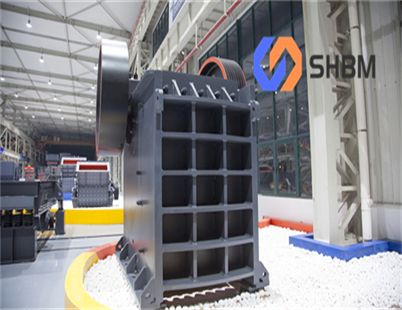

Jaw mobile crushing plant is also known as a coarse crushing tire mobile crushing station Therefore it is usually used for primary crushing small mobile jaw crusher plant adopts an integrated operation method which eliminates the installation of complex site infrastructure and auxiliary facilities The overall structure of the mobile jaw crushing

الاستفسار عبر الإنترنت →

Sandvik cone crusher series high performance low total cost Sandvik cone crushers are suitable for a wide range of applications within quarrying and mining segments End products for quarries include aggregates for concrete asphalt and railway ballast Our CS and CH cone crusher series combine extremely high performance with low total cost

الاستفسار عبر الإنترنت →

·Oil is pumped into or out of the cylinder below the piston by means of a hand pump in crusher sizes up to and including 48 in The larger Hydrocone crushers are equipped with a motor driven pump operated by push button control to speed up adjustment

الاستفسار عبر الإنترنت →

·Looking to optimize the performance of your crushing equipment while reducing maintenance costs and increasing safety It all starts with investing in high quality crusher wear parts This comprehensive guide covers everything you need to know about the different types of crusher wear parts their functions and factors to consider when

الاستفسار عبر الإنترنت →

·are designed to fit onto a 7 foot Symons cone crusher foundation thus saving on plant modification or building and foundation maintenance is very simple because of the push button disassembly Applications • Secondary and tertiary crushing for feeding grinding mills • HPGR s and leach pads

·Materials methods and equipment Before selecting an exact crusher it is important to first consider what crushing technology is needed for the feed material The two main methods used for crushing are fracture by energy or impact and compression or

الاستفسار عبر الإنترنت →

Grinding is one of the most energy consuming processes in the mining industry As a critical part of the comminution process autogenous grinding AG or semi autogenous grinding SAG mills are often used for primary grinding However the breakage mechanism of an AG/SAG mill is inefficient in grinding particles of a certain size typically in the range of 25

الاستفسار عبر الإنترنت →

·Crusher operating speed is adjusted by changing the diameter of the crusher and motor sheaves Each cone crusher has several cavity options with different feed openings and setting ranges The correct cavity can be selected based on the feed size setting and application

·Materials methods and equipment Before selecting an exact crusher it is important to first consider what crushing technology is needed for the feed material The two main methods used for crushing are fracture by energy or impact and compression or

الاستفسار عبر الإنترنت →

·We manufacture MP cone crusher liners with the same quality and committment as we do for our own crushers A large copper mine in South America contacted us for assistance with their pebble crusher The mine operates a MP 1000 cone crusher and was having difficulty achieving and maintaining their crusher s CSS setting

الاستفسار عبر الإنترنت →

It s particularly beneficial for tertiary and pebble crushing applications It brings you a revolution in intelligent crushing SAM by Sandvik gives you complete 24/7 access to data generated by your connected Sandvik crusher fleet Make decisions based on facts and clearly see areas where you can improve uptime and productivity

الاستفسار عبر الإنترنت →

By following these maintenance and troubleshooting tips diligently you can ensure that your river pebble sand machine operates smoothly and efficiently at all times Installing a ri ver pebble sand machine ca n greatly benefit your construction projects by providing high quality sand for various applications

الاستفسار عبر الإنترنت →

·Accommodates multiple maintenance practices Available for all mining class cone crushers Our tooling solution provides safety simplicity and efficiency for your maintenance teams Your needs matter to us Customers like you asked for a more efficient method to perform maintenance on our cone crusher head assemblies Our response

الاستفسار عبر الإنترنت →

·A semi autogenous SAG or autogenous mills AG circuit commonly comprises a pebble cone crusher to deal with the critical size particles The pebbles crusher is often oversized and thus not fully utilized The hypothesis put forward in this paper is that active control of the cone crusher s eccentric speed and closed side setting

الاستفسار عبر الإنترنت →

·1 Introduction The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1] [2] [3]] In recent years with the growth of the world s population the development of urbanization and the improvement of living standards the demand for the ore continues

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.