في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·The existing experimental and theoretical data regarding calcite are not entirely consistent and there is a lack of high pressure melting data Employing first principles molecular dynamics FPMD combined with the Z method we study the melting behavior of calcite at high pressures determining the melting temperature up to 370 GPa

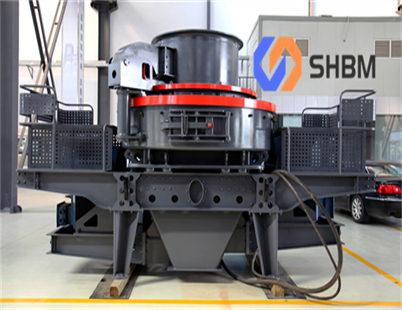

While most crushers used in the primary and secondary stages of crushing work by having two surfaces compress particles between them a vertical shaft impact VSI crusher instead relies on impact energy By having the rock particles flung against each other at high rates of speed the resulting impact creates a high

الاستفسار عبر الإنترنت →

·In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics will be

الاستفسار عبر الإنترنت →

For example in the mining industry it is generally necessary to use a primary crusher and a secondary crusher first and then a third or fourth type crusher if necessary to process coarse material According to the working principle crushing machines are divided into the following types cone crusher; jaw crusher; impact crusher

الاستفسار عبر الإنترنت →

·All research works are done on the impact horizontal crusher through modeling in SOLIDWORKS and Random Vibrational analysis was performed using ANSYS which showed the results for single design and various materials But the present work is concentrated on the materials which withstand impact load of the rock

While most crushers used in the primary and secondary stages of crushing work by having two surfaces compress particles between them a vertical shaft impact VSI crusher instead relies on impact energy By having the rock particles flung against each other at high rates of speed the resulting impact creates a high

الاستفسار عبر الإنترنت →

Spindle support rotor hammer crusher main parts bear the weight impact force from the rotor hammer thus requiring the spindle material has high strength and toughness the design uses a 35 silico manganese molybdenum vanadium steel end surface of the spindle the maximum diameter of 130 mm the bearing is 80 mm Hammer

الاستفسار عبر الإنترنت →

2 Both the structure and working of a jaw crusher are quite simple 3 The product size is quite small and can range up to millimetres 4 Repair and maintenance of a jaw crusher are convenient and easy 5 The reliability of a jaw crusher is significantly high 6 The broken parts of the jaw crusher are easy to replace Disadvantages of a Jaw

الاستفسار عبر الإنترنت →

Learn about the working principle applications and behavior of the Nicol prism Discover how this optical instrument is used in scientific research industrial quality control art conservation and medical imaging Understand the importance of polarized light and the role of Nicol prisms in manipulating and analyzing its properties

الاستفسار عبر الإنترنت →

·The heavy duty grizzly bars are constructed of cast manganese steel to withstand the impact and abrasive loads Colman and Tyler 1980 Vibrating screens are operated in the coal preparation plants to regulate the crusher product particle size deslime feed to heavy media separation circuits and also dewater the clean coal and rejects

الاستفسار عبر الإنترنت →

·Jaw crushers are widely used in mining smelting building materials industry highways railways water conservancy and chemical industries and many other sectors crushing various materials with compressive strength within 320 Working Principle Jaw crusher mainly consists of a frame an eccentric shaft a large pulley a

الاستفسار عبر الإنترنت →

horizontal vacuum belt filter images working principle Belt Filter Press dewatering A Belt Filter Press is a Biosolids/sludge dewatering device that applies mechanical pressure to a chemically conditioned slurry which is sandwiched between two 2 tensioned belts by passing those belts through a serpentine of decreasing diameter rolls

·This study presents an analytical mathematical model that elucidates the mechanics/kinematics of an impact crusher s impact swing mechanism Essentially this model comprises a series of mathematical descriptions and equations that are leveraged from established mechanical principles such as rigid body kinematics multibody

الاستفسار عبر الإنترنت →

·This paper introduced the structure and working principle of the vertical sharft impact crusher The determation of its main parameters is investigated in the first program and

الاستفسار عبر الإنترنت →

·What Is A Jaw Crusher And How Does It Work A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock gravel or dust It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it is broken into small pieces A stationary jaw plate and a movable jaw plate control

الاستفسار عبر الإنترنت →

·Blake Jaw Crusher Principle The Blake Jaw crusher is it works on the Principle of compression Construction of Jaw Crusher A schematic diagram of the Blake jaw Crusher is shown in Fig It has a fixed jaw and a movable jaw which is pivoted at the top The jaws are not set to form a V open at the top

الاستفسار عبر الإنترنت →

·Synchronous speed is the speed of rotation of the magnetic field in a rotary machine and it depends upon the frequency and number poles of the machine The induction motor always runs at speed less than its synchronous speed The rotating magnetic field produced in the stator will create flux in the rotor hence causing the rotor

الاستفسار عبر الإنترنت →

An Insight into the Working Mechanism An impact crusher primarily relies on the force of impact to crush materials Its principle of working is strikingly different from jaw and cone crushers that utilize compression to break down materials In an impact crusher when the materials enter the blow bar area they get hit by the high speed

الاستفسار عبر الإنترنت →

·We take a Φ900 x 900mm single rotor irreversible multi row hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone coal and other medium hardness ores It is mainly composed of a transmission device rotor lining

الاستفسار عبر الإنترنت →

·The compound crusher composite crusher is widely used in the crushing of various ore cement refractory materials bauxite clinker emery glass raw materials and special hard materials It is widely used in the crushing scope of mechanism construction of sand and various metallurgical slags and compared with other types of crushers it has

الاستفسار عبر الإنترنت →

·Plastic Crusher Machine is one of the Industrial crusher types and it is the fundamental equipment in the plastic injection industry It plays a unique role in the entire industry of plastic For the recycling process the waste plastic materials are collected and the final product to produce a new brand of plastic products

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.