في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

·IMPACT CRUSHER V belts 1 Bearings 2 Wearing parts 3 Exchange of wearing parts 4 Folding up the impact crusher housing 4 Blow bars 5 Impact aprons / Grinding path 6 Impact plates / Wear piece 6 BEARINGS WITH ADAPTER SLEEVES LUBRICATION Lubricating instructions 1 Table of

الاستفسار عبر الإنترنت →

·Choosing the right crusher wear parts can significantly impact equipment performance and maintenance costs Several factors should be considered when selecting the right wear parts Material being crushed Different materials have different hardness and abrasiveness levels which affect the wear and tear of the crusher wear parts

الاستفسار عبر الإنترنت →

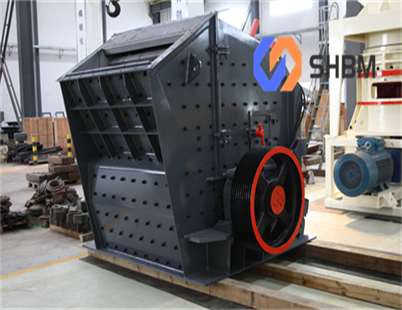

What are the benefits of an impact crusher Impact crushers reduce mineral materials such as concrete asphalt and natural rock in size to produce a valuable commodity product A fast spinning rotor throws the material against a solid stationary impact wall The striking and impacting causes the material to shatter into smaller pieces

الاستفسار عبر الإنترنت →

·Central part of the crusher Houses the crushing process Consists of the bowl liner fixed outer cone and mantle moving inner cone ; determines the size reduction ratio and overall performance A little 2 3 mm alteration in CSS can have a significant impact on product size distribution and capacity Crusher speed 1 Generally speaking

الاستفسار عبر الإنترنت →

4 ·Jaw crushers are mainly used as primary crushers in mining construction materials infrastructure and other sectors As the start of a high productivity crushing line using high quality replacement parts is crucial to extending the

الاستفسار عبر الإنترنت →

SWB develops produces and delivers impact crusher wear parts for vertical and horizontal impact crushing blow bars impact elements Tel 49 0 234 508 2 sales About us Collaboration; Sustainability impact crusher wear parts for horizontal and vertical

الاستفسار عبر الإنترنت →

5 ·Our customer service team is here to help you 24/7 Whatever you need we are here for you 86 157 9771 7019 sales

الاستفسار عبر الإنترنت →

·HSI Crusher Parts Square steel Liner Plates Side Liner Impact Rack Grinding Path Casting Material Chormium Cast Iron Martensite Alloy Steel Ceramic Inserts The manufacturing process is very rigorous to ensure a perfect fit with the NP1315 Impact Crusher

A jaw crusher is being replaced by the impact mill as part of upgrades to the system Screening curve of the impact crusher type PB 0806 when crushing iron and steel slag with 0 150 mm Impact crusher/mill type PB/PM for processing and refining metals from incinerator bottom ash IBA in a Swiss recycling plant

الاستفسار عبر الإنترنت →

High impact and high wear are common issues with impact crusher parts particularly with the hard rock quarries in Australia Used most often as secondary crushers on quarries and further down the circuit in larger mines impact crushers are expected to perform optimally to achieve the final product size and shape The right settings paired

الاستفسار عبر الإنترنت →

Discover premium aftermarket Metso impact crusher parts for various models which include Barmac B NP Lokotrack Urban Nordtrack and NW series Note The names of manufacturers part numbers model numbers images and descriptions are employed solely for reference and identification purposes These elements are the intellectual property

الاستفسار عبر الإنترنت →

·The importance of impact crusher wear parts including the blow bar cannot be overstated These parts are subjected to wear and tear and they need to be replaced regularly to ensure that the crusher operates efficiently A worn or damaged blow bar can lead to reduced crushing capacity increased maintenance costs and even

Impact wings To manufacture the impact wings KLEEMANN only uses hard manganese steel with excellent work hardening for maximum wear resistance The impact wings stand out for their long service life due to the thick walled wear layer and optimum crushing results due to their special design

الاستفسار عبر الإنترنت →

2 ·Jaw crushers are mainly used as primary crushers in mining construction materials infrastructure and other sectors As the start of a high productivity crushing line using high quality replacement parts is crucial to extending the

الاستفسار عبر الإنترنت →

·HSI Crusher Parts Square steel Liner Plates Side Liner Impact Rack Grinding Path Casting Material Chormium Cast Iron Martensite Alloy Steel Ceramic Inserts The manufacturing process is very rigorous to ensure a perfect fit with the NP1315 Impact Crusher

الاستفسار عبر الإنترنت →

Dual hardened hammers or bi metallic hammers for hammermills In this type of hammer the wearing part or head of the hammer is 60 62HRC giving maximum wear resistance especially with highly abrasive feeds The fixing or mounting part of the hammer is around 200BHN which gives the hammer good tenacity and impact resistance

الاستفسار عبر الإنترنت →

·The Finlay® I 140 tracked impact crusher shapes the future through innovation This new generation impact crusher with redefined style and advanced technological design gives improved material flow and production capabilities in quarrying mining demolition and recycling applications

الاستفسار عبر الإنترنت →

A professional reliable Chinese supplier of crusher wear parts high maganese/high chrome wear parts wear resistant castings precision castings marcus 86 136 17316392 86 139 2922 2957 Jaw Crusher Wear Parts Impact Crusher Wear Parts Metso parts S Contacts Address 3108 1 14

الاستفسار عبر الإنترنت →

Ring Granulator also known as Ring Hammer Mill is a crusher that operates at relatively low speeds and has large reduction ratio It has multiple rows of Ring Hammers which crush material by a combination of Impact and rolling compression

الاستفسار عبر الإنترنت →

·Our Impact Crusher Wear Parts Performance AMCAST s Research and Development team has developed Patented alloys and Wear Resistant Inserts that deliver the best crusher wear parts performance in the industry MasterCeramic TM Inserts for Heavy Duty Applications Blow Bars VSI Shoes & Anvils Breaker Plates;

الاستفسار عبر الإنترنت →

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.